Application / Solutions

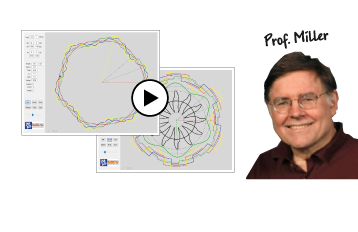

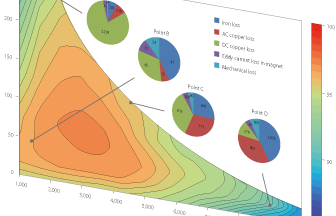

Motor Design

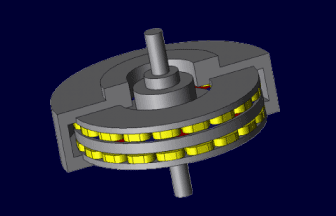

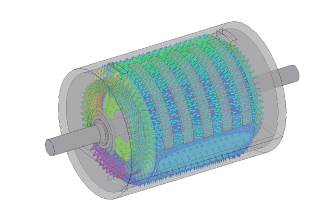

Axial Gap Type Motor

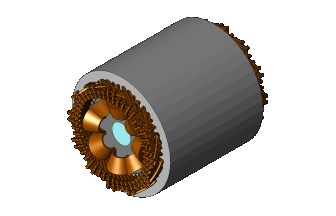

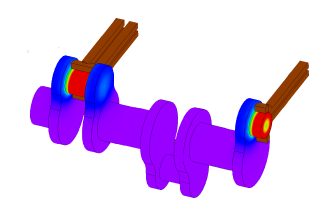

Wound Field Synchronous Motor

Induction Heating

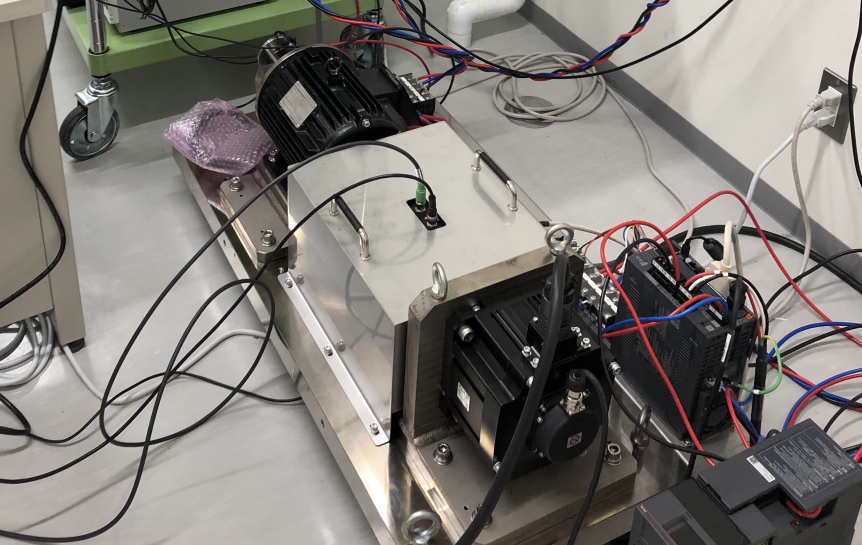

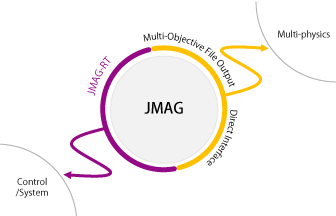

Model-Based Development

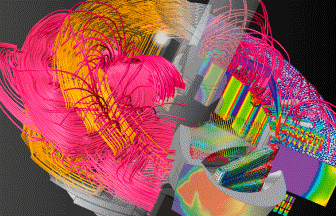

Thermal Analysis for Motor Design in JMAG

Utilizing JMAG in Cloud Services

JMAG Open Interface programs

Case studies by users and applications for JMAG open interface programs are also available on this page. Upd