A new stage in induction heating analysis

2023-11-24

Challenge phase transformation

2023-11-24

To obtain highly accurate efficiency maps

2023-11-24

sustainable design

2023-11-24

Virtual calibration with JMAG-RT

2023-11-22

High precision cogging torque analysis

2023-11-22

History and future of iron loss modeling

2023-11-22

Featured JMAG-Express usage examples

2023-11-22

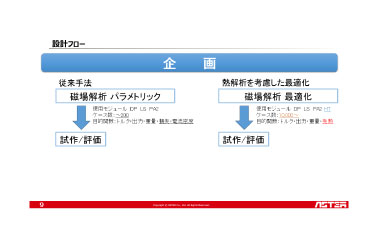

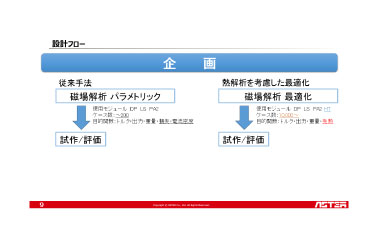

Challenge to shorten analysis flow

2023-11-22

Power density 12kW/kg

2023-11-21

Vibration problem at extremely high speeds

2023-11-20

Challenge to search for limit performance

2023-11-20

A model for topology optimization

2023-11-17

Optimization calculations also become hybrid

2023-11-17

JMAG user group around the world

2023-11-15

Average torque doesn’t match!?

2023-11-13

Early bird offer ends soon

2023-11-13

Highlights of the exhibition

2023-11-10

40th anniversary of JMAG

2023-11-09

Translated via Google Translate

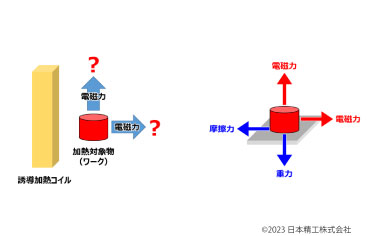

It would be great if there were many things that could be solved based on experience and past achievements, but there are many cases where this is not possible. On the contrary, I think they can become constraints and prevent breakthroughs. One of the great things about CAE is that you can forget those constraints and bounce ideas around. However, because CAE is not a panacea, evaluations are usually made based on some kind of approximation, and what can be considered is still limited.

It would be great if there were many things that could be solved based on experience and past achievements, but there are many cases where this is not possible. On the contrary, I think they can become constraints and prevent breakthroughs. One of the great things about CAE is that you can forget those constraints and bounce ideas around. However, because CAE is not a panacea, evaluations are usually made based on some kind of approximation, and what can be considered is still limited.

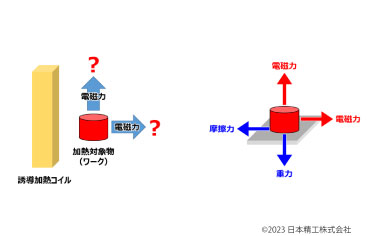

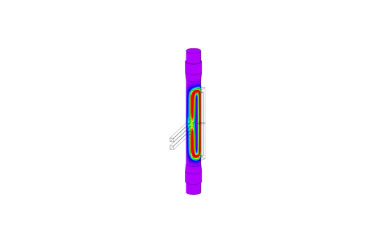

The three-coupled function of magnetic field, heat, and structural analysis helps overcome this limitation. For example, in induction heating, the scope of evaluation expands to include workpiece deformation, workpiece movement due to electromagnetic force, and changes in the force balance position. This will expand consideration in areas that previously had to rely on actual objects, and may lead to some kind of breakthrough.

Why not be inspired by NSK’s new initiatives?

12/7 17:10-17:40

Induction heating session: Mr. Go Hagimoto, NSK Ltd.

Analysis of Electromagnetic Force Acting on a Workpiece During Induction Heating

2023-11-24Michiaki Suzuki

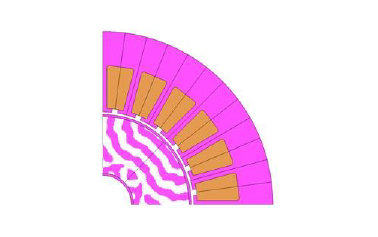

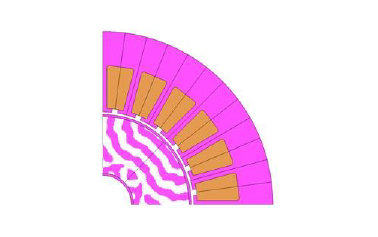

I think many people have experienced firsthand that the motor-related industry is becoming more active as electrification progresses. Shrink fitting of motor cases using induction heating is one example.

I think many people have experienced firsthand that the motor-related industry is becoming more active as electrification progresses. Shrink fitting of motor cases using induction heating is one example.

NIPPON THERMONICS CO.,LTD, which will be giving a lecture, has been focusing on the industrial application of induction heating from an early stage, and has a track record of 50 years since its founding. Although it has only been a short time since JMAG was introduced, it is already being used for optimization calculations.

In this presentation, we will not only report on an example of how optimization was used to design a coil for motor shrink-fitting, but also an example of how optimization calculations were used to consider power supply specifications in the early stages of developing a heating device (system design). I’ll enjoy having this. This will help you select more reasonable specifications when selecting power supply equipment.

I hope that you will find this lecture useful in your own work.

12/7 16:40-17:10

Induction heating session: Mr. Keisuke Ando, NIPPON THERMONICS CO.,LTD

Optimizing Motor Shrink Fitting Process Conditions Using Induction Heating

2023-11-24Michiaki Suzuki

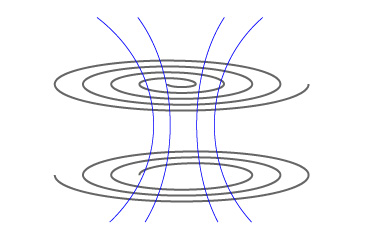

Recently, the number of people using JMAG to conduct induction heating analysis has increased.

Recently, the number of people using JMAG to conduct induction heating analysis has increased.

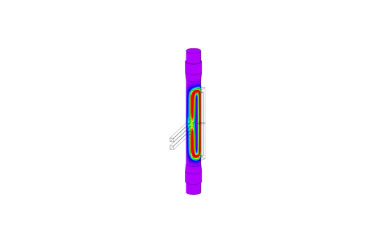

When dealing with induction hardening in analysis, it is difficult to accurately represent eddy currents including skin effects, so JMAG is used by many people for induction heating.

However, in order to achieve the required precision in induction hardening, for example, eddy current loss and temperature distribution alone may not be sufficient. This is because it may be necessary to consider deformation, stress, structural changes, etc.

Therefore, more and more analyzes are coupling structural analysis to induction heating analysis, or taking phase transformation into consideration.

In the lecture by Mr. Ohnuma from NDK Inc. we collaborated with JMAG and Simufact to take on the challenge of induction hardening analysis that takes phase transformation into consideration.

Examples of cooperation between JMAG and Simufact have not been presented at the JMAG User Meeting so far, so those interested in induction heating analysis are encouraged to attend.

12/7 16:10-16:40

Induction heating session: Mr. Ippei Ohnuma, NDK Inc.

Initiatives in Induction Hardening simulation by Coupling JMAG and Simufact

2023-11-24Tetsuya Hattori

When simulating a vehicle’s thermal management system, leave the magnetic field + thermal model of the drive motor to JMAG.

When simulating a vehicle’s thermal management system, leave the magnetic field + thermal model of the drive motor to JMAG.

However, when it comes to thermal models for things other than motors, such as oil coolers, oil pumps, and radiators, unfortunately JMAG cannot model them.

On the other hand, there are many 1D system simulation software that already have thermal models for each component of the vehicle, such as the radiator.

When considering system simulation, it is not necessarily necessary to create a system using a single software; it is better to connect software that specializes in simulating models for each component in order to achieve efficient and highly accurate simulations.

In this lecture, he will introduce the construction of a simulation environment for a thermal management system for drive motors linked to vehicle systems by connecting specialized software called JMAG and Amesim.

By using this simulation environment, motor magnetic circuit designers can predict temperature changes in the motor while the vehicle is running.

Please check out the lecture to learn more about this simulation environment that everyone dreams of.

12/7 13:40-14:10

MBD session: Mr. Mizuki Minami, DAIHATSU MOTOR CO., LTD.

Establishing Thermal Analysis Method for Motors by Coupling JMAG x Amesim

2023-11-24Masahiko Miwa

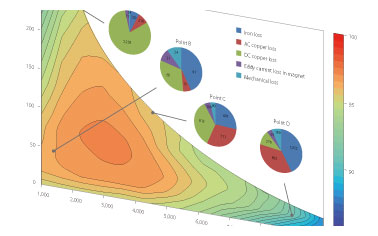

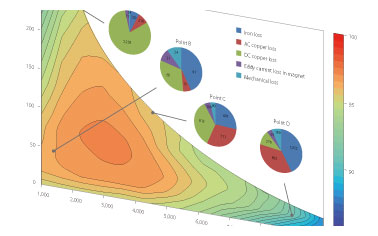

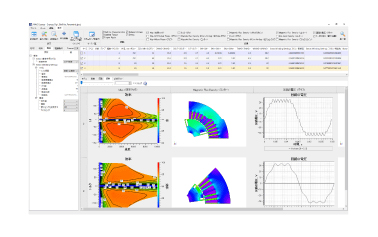

Nowadays, as competition in EV development becomes more intense, what does it take to design and develop a motor in a few weeks to a month?

Nowadays, as competition in EV development becomes more intense, what does it take to design and develop a motor in a few weeks to a month?

One way to correctly evaluate motor characteristics is to prepare a highly accurate efficiency map.

The key is to evaluate AC loss, which is particularly difficult to measure.

We will simply introduce how United Automotive Electronic Systems Co., Ltd. solves this problem, including actual measurement results.

This is a good opportunity to learn about their modeling methods and more. Please come and join us.

12/7 10:40-11:10

MBD Session: Dr. Li Chen, United Automotive Electronic Systems Co.,Ltd.

Validated Efficiency Simulation of Electrical Machine based on JMAG-Designer

2023-11-24Mari Nakamura

We will talk about vibration evaluation of drive motors for EVs. This may sound like a general case study introduction, but as I purposely called it a “virtual prototype,” we modeled it in 3D, including electromagnetic field analysis and eccentricity, and evaluated it on a simulation basis, including vibration analysis. This is an example of what happened.

We will talk about vibration evaluation of drive motors for EVs. This may sound like a general case study introduction, but as I purposely called it a “virtual prototype,” we modeled it in 3D, including electromagnetic field analysis and eccentricity, and evaluated it on a simulation basis, including vibration analysis. This is an example of what happened.

This is a good example of a straightforward model without simplification and detailed analysis.

For example, I would like to discuss with everyone on the day the existence of force components that cannot be considered when modeling electromagnetic field analysis using 2D multi-slices, and the magnitude of their effects.

You can listen to the lecture in Japanese and ask questions, so please feel free to join us.

12/7 9:00-9:30

Vibration Session: Dr. Jacob Krizan, Ford Motor Company

Development of a Detailed 3D Eccentric eMotor Model for Electric Vehicle NVH Simulations

2023-11-24Yusaku Suzuki

Canned motors are used in a variety of applications and locations, such as air conditioners and plants.

Canned motors are used in a variety of applications and locations, such as air conditioners and plants.

These systems are the foundation of society, so once they are installed, they must be operated safely for a long period of time.

For long service life, excessively high temperatures of the coil must be avoided.

The lecture by Ryuki Haruna of Teikoku Electric Manufacturing Co., Ltd.

is about an effort to predict the temperature of a canned motor using simulation rather than actual measurement.

In motor temperature prediction by simulation,

- In the first place, is the loss prediction (magnetic field analysis result) correct as a heat source?

- Can cooling and contact between objects be accurately expressed?

There are challenges like this.

Will JMAG’s thermal analysis really make this possible?

(Of course I would like to say yes!, but I would like to listen to the lecture with excitement.)

12/6 17:00-17:30

Thermal session: Mr. Ryuki Haruna, TEIKOKU ELECTRIC MFG. CO., LTD.

Coupled Analysis of Induction Motor using JMAG-Express

2023-11-24Kazuki Senba

As sustainability is becoming more important in the automobile and aviation industries, sustainability is now required in design as well.

As sustainability is becoming more important in the automobile and aviation industries, sustainability is now required in design as well.

This means developing a V-shaped cycle based on a model, and development progresses by moving back and forth from the system level to the component level.

In this lecture, he will introduce the process of introducing simulation from the early development stage and performing optimization while simultaneously evaluating basic characteristics (efficiency maps) and thermal design.

I would like to hear this from anyone who is thinking about how to apply JMAG-Express to their design process.

12/6 14:30-15:00

Concept Design Session: Mr. BALASUBRAMANI K, SIMPSON & COMPANY LIMITED

Sustainable Motor Architecture through Optimization Techniques in JMAG

2023-11-24Hiroyuki Sano

Two styles coexist at the JMAG User Group social gathering.

1) Enjoyable chats

2) Exchange of technical information that was not enough during communication time

Although it is only for a short time, it is a place where speakers, exhibitors, participants, customers, and JSOL members gather.

If you want to have fun chatting with others, but also if you don’t like alcohol or don’t like people, why not stay for a little while?

I once had a customer who invited me to a social gathering say, “I don’t want to attend because I don’t have anything to talk about.”

In such cases, please complain about JMAG to JSOL members. In addition, when she praises us and says, “It’s been great here,” it makes us work harder.

Most of the participants in the JMAG User Group are technical people. Although the companies and products are different, these are people who are searching for good manufacturing.

Even if you have not participated before, please consider participating.

12/6 18:30-20:00 Reception: Let’s discuss the issues and future of JMAG.

2023-11-22Marketing team

When we tried manufacturing and evaluating a prototype based on the results of optimization calculations, we found that the output was not as expected from the theoretical study. . Some of you may have had similar experiences.

When we tried manufacturing and evaluating a prototype based on the results of optimization calculations, we found that the output was not as expected from the theoretical study. . Some of you may have had similar experiences.

In this case, I think you will need to review the design again to ensure that the required performance is met.

Why couldn’t the output match the results of the desk study? There may be various reasons for this, but I think one of them is that performance variations due to manufacturing errors were not taken into account.

In order to eliminate design rework, manufacturing errors should be taken into consideration from the design exploration stage to determine a good plan. I think this is something that cannot be avoided as we move forward with design automation.

This time, we received a valuable lecture from Denso Corporation that will be useful for everyone in the future, such as how to understand optimization calculations that take into account performance variations within a practical time.

How can we determine a good plan that takes into account variations?

In the first place, just to understand the dispersion would require a certain amount of data, but is it possible to do it within a realistic amount of time, including optimization?

I hope that you will listen to this lecture and find this information useful.

I think this lecture is a must-listen for everyone involved in electrical equipment design. Please take a look.

12/7 17:10-17:40

Optimization session: Mr. Takuya Yoshioka, DENSO CORPORATION

Practical Robust Optimization Method using HPC

2023-11-22Shiro Yano

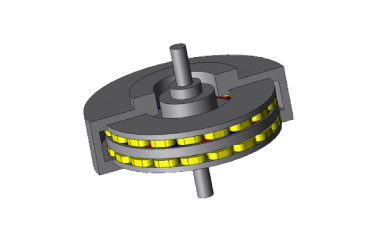

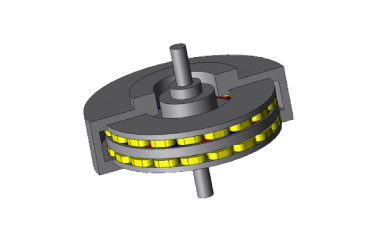

Axial flux motors have been in great demand in recent years, but do you have any problems when trying to evaluate design proposals through simulation?

Axial flux motors have been in great demand in recent years, but do you have any problems when trying to evaluate design proposals through simulation?

It is essential to express the three-dimensional flow of magnetic flux due to its structure and mechanism, and it is necessary to use a three-dimensional model for analysis, which requires an enormous amount of calculation time. I guess it will happen.

In this lecture, we will talk about our approach to optimization calculations for axial flux motors, which are plagued with such problems.

We tried meshing and simplification techniques to reduce the model size without sacrificing accuracy, tuned solver parameters to solve the problem at high speed, improved the HPC environment, and derived useful answers through optimization calculations. It is packed with essential elements for 3D analysis and its optimization, including efforts to complete a sufficient number of calculation cases in a practical amount of time.

This is a must-listen for those who want to work on optimization, those who are working on it, and those who are interested in 3D analysis.

Please take a look.

12/7 16:40-17:10

Optimization session: Mr. Florian Birnkammer, Rolls-Royce Deutschland Ltd & Co KG

Electrical Power & Propulsion Systems for Advanced Air Mobility

3D Design Space Exploration of an Axial Gap PMSM

2023-11-22Yohei Wakisaka

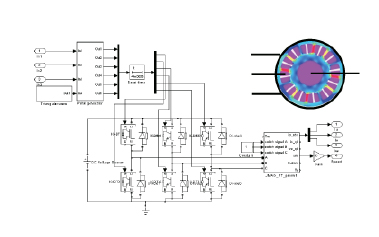

Verification and adaptation of ECUs is very time consuming. It is my understanding that engine ECU verification was performed on the bench and through HIL and MIL. With electrification, engines are replaced with electric motors, and even higher levels of performance will be required as verification items, but a greater proportion of this can now be done with simulations rather than with actual machines.

Verification and adaptation of ECUs is very time consuming. It is my understanding that engine ECU verification was performed on the bench and through HIL and MIL. With electrification, engines are replaced with electric motors, and even higher levels of performance will be required as verification items, but a greater proportion of this can now be done with simulations rather than with actual machines.

This lecture will begin with an introduction to the verification environment, including HIL and MIL, and will include an example of desktop calibration using a high-precision motor model: JMAG-RT. Please feel free to ask questions and discuss how we achieved front loading on the day.

12/7 14:10-14:40

MBD session: Mr. Nobuo Morimura, SUBARU CORPORATION

Applied Cases of EV Motor Controller Tuning by MILS using JMAG-RT

2023-11-22Yusaku Suzuki

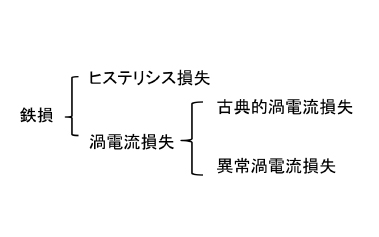

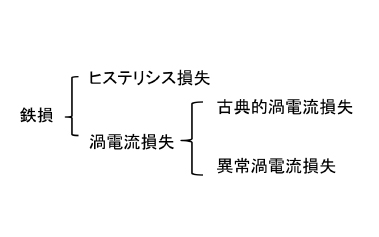

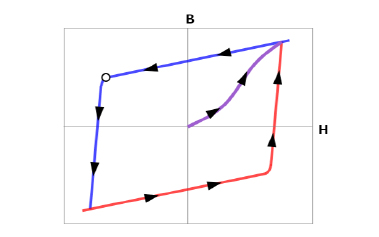

The mechanism of iron loss is complex, and modeling is still being studied.

The mechanism of iron loss is complex, and modeling is still being studied.

Although we calculate iron loss every day, it may be questionable if we fully understand how iron loss is modeled. To understand models of iron loss, especially abnormal eddy current loss, it is necessary to consider microscopic phenomena such as domain wall movement.

In this lecture, materials expert Arcelor Mittal Sigrid Jacobs will provide an explanation and comparison of loss models.

Although the time is short, the content provides a deep understanding of loss analysis, and there is a great learning experience not only for those who are just learning loss analysis, but also for those who are currently working on it.

12/7 10:10-10:40

Materials Session: Ms. Sigrid JACOBS / Dr. Jan RENS, ArcelorMittal

Comparing Numerical with Statistical Iron Core Loss Modelling Approaches for Application in Automotive Traction Electrical Machines.

2023-11-22Hiroyuki Sano

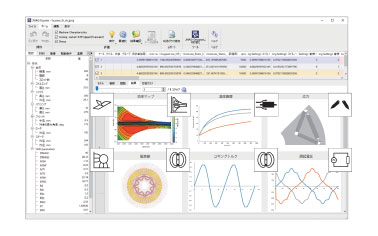

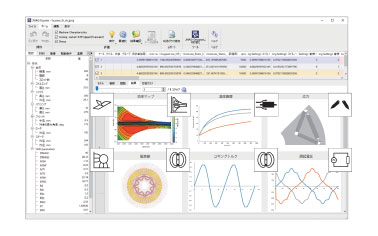

JMAG-Express performs multifaceted evaluation to satisfy performance requirements and immediately requests design proposals.

JMAG-Express performs multifaceted evaluation to satisfy performance requirements and immediately requests design proposals.

JMAG’s strength is that it allows design exploration to be carried out through wide-ranging and high-speed trials, from concept design to detailed design.

By incorporating the strengths of JMAG, it is possible to develop in a shorter time and at lower cost.

In this lecture, he will explain why he decided to incorporate JMAG, as well as the new development flow and effects created by it.

Please come and listen to the popular JMAG-Express usage examples.

12/6 15:00-15:30

Concept Design Session: Mr. ChiLu Lee, Vast Power Corporation

Analysis and Optimization of Motors for Electric Vehicles

2023-11-22Mari Nakamura

As you all know, the goal of MBD is to use models in the early design stage to repeat tests and analyzes without prototyping, thereby shortening construction times and improving product quality by reducing rework.

As you all know, the goal of MBD is to use models in the early design stage to repeat tests and analyzes without prototyping, thereby shortening construction times and improving product quality by reducing rework.

In this lecture, with the theme of loss evaluation, which is sure to rank among the top problems in motor design, we will focus on the drive unit and discuss how to incorporate it into system simulation while maintaining the calculation accuracy of motor loss as a component. We will introduce the theory and its application examples.

The accuracy of each simulation result for each component and system is verified by comparing it with actual measurements, and you will be able to feel the persuasiveness of the method he introduced as well as the power of his lecture.

This book will be of particular interest not only to those involved in system simulations involving motors, but also to those who are troubled by the trade-off between accuracy and calculation time required for motor models and are forced to choose a compromise. Please take a look.

12/7 11:10-11:40

MBD Session: Mr. Nicola Rossi, Rimac Technology

Enabling Full EDU Optimization and Losses Analysis Under Different PWM Strategies and DC Voltages Employing Combined JMAG-Matlab Simulation Environments

2023-11-22Yohei Wakisaka

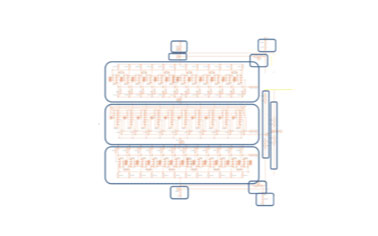

Development periods are becoming shorter due to shorter product cycles.

Development periods are becoming shorter due to shorter product cycles.

Simulation has now become an established part of product development, and improving the simulation analysis flow is also an important issue.

This time, Hitachi High-Tech Corporation will give a lecture on their efforts to shorten the analysis flow of medical blood analyzers.

This device requires fluid-magnetic field coordination, and while fluid analysis is highly accurate, it poses challenges in analysis preparation time and analysis time.

The company has established a method of expressing fluid effects using user subroutines in the early stages of analysis, and handling them qualitatively using JMAG-Designer alone.

The content will be very helpful for those who have issues with shortening the analysis flow, so please come and see us.

12/7 09:30-10:00

Introduction session: Mr. Shigeru Yamamoto, Hitachi High-Tech Corporation

Study of Magnetic Structure for Capturing Magnetic Particles in Fluid

2023-11-22Takashi Nakaoka

JMAG has long enabled motor design through multi-objective optimization that takes into account thermal and structural design variables in addition to magnetic fields.

JMAG has long enabled motor design through multi-objective optimization that takes into account thermal and structural design variables in addition to magnetic fields.

By conducting such multifaceted evaluations from the early stages of design, it is possible to reduce rework and obtain more realistic design proposals.

In the future, the scope of evaluation will further expand, including evaluation of insulation resistance.

And such studies have already begun at actual design sites.

We will present a case study of a drive motor, which shows what kind of design proposal can be obtained by actually incorporating a design flow based on optimization that takes insulation and EMC into account.

As the DC bus voltage of drive motors increases, damage to bearings due to shaft current has become a new issue, and we will also be asked to report on the need for optimization, including electric fields.

Please come and listen to the very interesting presentations on how to calculate stray capacitance, evaluate shaft current, and incorporate it into optimization.

12/7 16:10-16:40

Optimization session: Mr. Mohamed Essam Ahmed, AVL List GmbH

Coupled Optimization of Active and Passive Components in Electric Machines: Towards Performance, Efficiency, Reliability and EMC Objectives

2023-11-21Mari Nakamura

Cogging torque analysis is one of the most difficult topics to achieve accuracy in magnetic field analysis.

Cogging torque analysis is one of the most difficult topics to achieve accuracy in magnetic field analysis.

Throughout the history of finite element magnetic field analysis, methods of cutting meshes with low noise have been considered.

However, as the cogging torque becomes lower, higher accuracy is required for analysis.

Since cogging torque is caused by a slight imbalance in magnetic resistance, it is necessary to refine the magnetic characteristics in order to improve the accuracy of cogging torque analysis.

In this presentation, he will present how much the accuracy of cogging torque analysis has been improved by considering hysteresis and machining distortion.

A must-see for those who want to improve the accuracy of magnetic properties.

12/7 11:10-11:40

Materials session: Mr. Takaya Sugimoto, Nidec corporation

Improvement of Cogging Torque Analysis Accuracy using Material Modeling Function of JMAG

2023-11-22Hiroyuki Sano

Power density 12kW/kg. Those involved in the development of drive motors and motor drive systems for electric aircraft and electric vehicles will appreciate this high level of performance. H3X Technologies , located in Colorado, USA Do you know this company? The company is developing an electric propulsion system with an integrated inverter and gearbox that includes a high-power density electric motor for electric aircraft.

Power density 12kW/kg. Those involved in the development of drive motors and motor drive systems for electric aircraft and electric vehicles will appreciate this high level of performance. H3X Technologies , located in Colorado, USA Do you know this company? The company is developing an electric propulsion system with an integrated inverter and gearbox that includes a high-power density electric motor for electric aircraft.

In the lecture, he talked about how he challenged the assumptions and limits of existing motor designs and how he utilized simulations, mainly from the perspective of efficiency maps, in order to achieve higher power density as a system. Please share. It is also possible to listen in Japanese, so please come and join us.

12/7 10:10-10:40

MBD Session: Mr. Max Liben, H3X Technologies

H3X Integrated Motor Drives: Delivering World-Class Power Density for Maximum Vehicle Range

2023-11-21Yusaku Suzuki

Highly accurate evaluation of loss through electromagnetic field analysis is essential when aiming for automatic motor design and no prototype production.

Highly accurate evaluation of loss through electromagnetic field analysis is essential when aiming for automatic motor design and no prototype production.

Therefore, various methods have been developed to deal with the losses that occur in the laminated core of a motor.

However, processing deterioration and loss in magnetic properties that occur during laminated core molding include structural factors such as residual stress and cross-sectional deformation, so it can be said to be a type of loss that is difficult to handle in electromagnetic field analysis.

This lecture describes a method for analyzing the effects of cross-sectional deformations such as sag and burrs that occur during die punching of laminated cores on loss.

Users can easily use this proposed method, as it is a method that simply replaces the deterioration of magnetic properties due to cross-sectional deformation with a change in magnetic resistance.

Please take a look at this proposed method, which can be said to be at the forefront of high-accuracy loss evaluation of laminated cores, at the lecture.

12/7 14:10-14:40

Materials session: Mr. Yu Hirotani, Mitsubishi Electric Corporation

Modeling Study of Magnetic Properties in Stator Cores with Splits in the Core Back Region and Study of Application to Design

2023-11-21Masahiko Miwa

During the magnetization process, the magnetizing magnetic field changes over time when the magnetized object moves or when the current value is changed multiple times.

During the magnetization process, the magnetizing magnetic field changes over time when the magnetized object moves or when the current value is changed multiple times.

To deal with such cases, we have released a function in JMAG-Designer 22.0 that allows one magnetized material to be magnetized multiple times (hereinafter referred to as the multiple magnetization function).

This time, Power Supply Technology Co., Ltd. will give a lecture on issues and improvements to extrusion molding machines.

Because the magnetized material moves during extrusion, analysis requires the ability to magnetize multiple times.

In his lecture, he will talk about the ability of analysis to reproduce trends in actual measurements and how he will consider improving issues.

This is a must-see for those who are considering magnetization, so please give it a listen!

12/7 13:40-14:10

Materials session: Ms. Mayu Maruyama, Power Supply Technology Co., Ltd.

Power Supply Technology Co., Ltd. (Abbreviated: PST)

2023-11-21Takashi Nakaoka

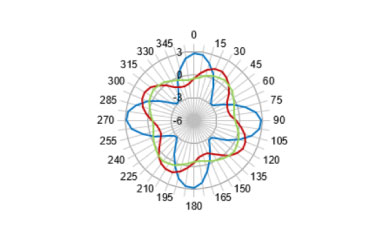

For those of you who use JMAG for simulations, I think you always have the theme of whether something matches or doesn’t match actual measurements.

For those of you who use JMAG for simulations, I think you always have the theme of whether something matches or doesn’t match actual measurements.

Even physical phenomena that seem simple at first glance may not match actual measurements if you ignore the key points.

This is because, for better or worse, JMAG is nothing more than a calculator that outputs correct results based on input, and it does not judge whether the input is good or bad for evaluation items.

For example, regarding magnetic properties, approximate characteristics such as the average magnetization curve and normal magnetization curve have been used until now.

Although this may provide a good fit in some cases, it cannot capture physical phenomena that are significantly affected by magnetic hysteresis.

In this lecture, he will discuss his efforts to improve simulation accuracy by refining material properties.

The article focuses on not only simulation but also actual measurement, and introduces the experience of being able to achieve accurate evaluation only by thoroughly examining both aspects.

We are confident that the content that we have noticed and considered because we are users in the field, not software vendors, will definitely be useful to you.

12/7 10:40-11:10

Materials Session: Mr. Ryoma Yamamoto, Kawasaki Heavy Industries, Ltd.

Initiatives in Improving the Design Accuracy and Performance of Magnetic Bearings

2023-11-21Taizo Senda

In order to make motors smaller, it is expected that motors will continue to have higher rotation speeds.

In order to make motors smaller, it is expected that motors will continue to have higher rotation speeds.

Due to the high rotation speed, there are cases where conventional measures cannot be used.

Even if vibration problems can be solved with conventional rotation speeds, new issues such as bending resonance of the shaft may arise due to higher rotation speeds.

In his lecture, Mr. Maeda of Estech Co., Ltd. examined the vibration problem that will become an issue due to high rotation speeds in the future.

There may not be many people currently working on high-speed rotation, but I think this is a vibration study that will be needed in the future, so I would like to hear from as many people as possible.

12/7 9:30-10:00

Vibration session: Mr. Takashi Maeda, ESTECH Corporation

Investigation of the Effect on Electromagnetic Excitation Force Considering Dynamic Eccentricity in Ultra-High Rotation Motor

2023-11-20Tetsuya Hattori

Motor temperature is an important design requirement because of the upper temperature limit for the coil insulation type and the possibility of causing thermal demagnetization of the magnet.

Motor temperature is an important design requirement because of the upper temperature limit for the coil insulation type and the possibility of causing thermal demagnetization of the magnet.

Do you have the impression that in order to predict temperature, analysis such as CFD is required, which is difficult and does not match the actual equipment?

By constructing a thermal circuit by analyzing the motor structure, cooling, and contact resistance in detail, even motor magnetic circuit designers can predict temperature at the initial design stage.

Mr. Shimagaki of the Japan Aerospace Exploration Agency, a national research and development agency, presented an example of predicting the temperature of a motor placed in the extreme environment of a rocket fuel pump at the design stage and examining whether the thermal design was valid. Masu.

As electrification progresses and motors are required to have higher output density, the importance of thermal design is increasing. I hope this lecture will be helpful to you, so please take a look.

12/6 18:00-18:30

Thermal session: Ph.D. Mitsuru Shimagaki, Japan Aerospace Exploration Agency

Thermal Problem of the 200kW Class High-Speed Rotation Axial Gap Motor Applied to the Uniaxial Electric Pump for the Cryogenic Propellant Supply of the 30kN Thrust Class Liquid Rocket Engine (Study using JMAG Results and CFD-Thermal Coupled Analysis)

2023-11-20Katsuyuki Narita

One of the factors that limits motor output is temperature. In many cases, the coil temperature

One of the factors that limits motor output is temperature. In many cases, the coil temperature

becomes a constraint, which limits the output and rotation speed.

When designing a motor, the conventional method was to find a shape that satisfies the requirements of the magnetic circuit and then move on to temperature, strength, and vibration evaluations.

Even if optimization is used, most people will explore the magnetic circuit and then move on to subsequent evaluations. In that case, it is difficult to find out where the performance limit is based on thermal requirements, and I feel that it is difficult to make a breakthrough.

In this presentation, he will report the results of his efforts to search for a design plan that maximizes output density while taking into account temperature constraints through thermal analysis during optimization calculations. I think it will be helpful for those aiming for high power density such as motors for drones and aircraft. Why not visit the venue on the day of the lecture?

12/6 17:30-18:00

Heat session: Mr. Kyohei Yanagisawa, ASTER CO.,LTD

Application of the Heat Generation Analysis Function to Motor Optimization

2023-11-20Michiaki Suzuki

Motor technology has a history of over 100 years, and it appears that the principles and theories have already been established. Therefore, many of the motors designed today may be roughly patterned.

Motor technology has a history of over 100 years, and it appears that the principles and theories have already been established. Therefore, many of the motors designed today may be roughly patterned.

However, modern vehicle drive motors in particular require higher power density and efficiency that cannot be achieved using traditional design patterns.

In order to achieve this, it is necessary to devise a new motor that differs from conventional principles.

This lecture introduces a motor developed using completely new principles such as the use of three-dimensional magnetic paths, asymmetrically arranged magnets, and variable magnetic flux.

The proposed motor may become the mainstay of future vehicle drive motors.

Through this lecture, please be sure to check out the latest motor technology that is expected to make further progress in the future.

12/6 14:30-15:00

Large-scale session: Mr. Yutaro Hiyoshi, Yamaha Motor Co., Ltd.

Operating Characteristics of Adjustable-field Permanent Magnet Motors with 3D Magnetic Paths and Asymmetric Magnet Arrangement

2023-11-17Masahiko Miwa

There are software vendors who repeat like a mantra, “Three-dimensional analysis is important, so everyone should do it.” (I think it’s called JMAG) I sometimes

There are software vendors who repeat like a mantra, “Three-dimensional analysis is important, so everyone should do it.” (I think it’s called JMAG) I sometimes

get questions like, “I don’t need it because it takes time,” or “I don’t need it because I can design it without doing it.”

However, what if three-dimensional analysis of a motor involving millions of elements, including drifting loss and eddy current loss, could be performed multiple times a day, and the deviation from actual measurements could be reduced by cutting an appropriate mesh?

The lecture by Daisuke Misu of Toshiba Infrastructure Systems Corporation will directly answer the above questions.

Instead of just blindly subdividing the mesh, engineers should think about what they want to know through large-scale analysis when modeling.

What points should we focus on in the analysis results?

The content is thought-provoking. We look forward to hearing from you.

Something I’ve been thinking about recently:

When calculating using many cores, the power consumption is not small.

As we encourage everyone to use HPC, are we contributing to energy savings?

The only way to improve the efficiency of equipment around the world is to have everyone who uses JMAG design highly efficient electrical equipment.

We need to develop useful software.

12/6 15:00-15:30

Large-scale session: Mr. Daisuke Misu, Toshiba Infrastructure Systems & Solutions Corporation

Verification of Motor Component Losses Using Large-scale Analysis

2023-11-17Kazuki Senba

In recent years, motors with an axial gap (axial flux) structure have been attracting attention because they are flat and can achieve high torque density.

In recent years, motors with an axial gap (axial flux) structure have been attracting attention because they are flat and can achieve high torque density.

The problem with the design and analysis of axial gap motors is that the flow of magnetic flux is three-dimensional, and three-dimensional analysis may be essential.

Mr. Ota of Meidensha Co., Ltd.’s lecture showed an example of speeding up a parallel solver (MPP), and he said that he might be able to get a sense that 3D analysis does not actually take as much time as you think.

We will also be able to discuss topics other than detailed three-dimensional analysis, so please take a look.

(There’s also talk that JMAG’s functions haven’t quite caught up to that point…)

12/6 14:00-14:30

Large-scale session: Mr. Satoru Ota, MEIDENSHA CORPORATION

The Faster Analysis of the Axial Gap Motor using JMAG

2023-11-17Katsuyuki Narita

Topology optimization, which has a high degree of freedom in shape, is attracting attention as a novel motor design method.

Topology optimization, which has a high degree of freedom in shape, is attracting attention as a novel motor design method.

But NGnet? radius? Placement? There are parameters that are unfamiliar to those who have not tried topology optimization yet, and some people may give up on topology optimization because they do not know how to adjust these parameters. .

In this lecture, using a synchronous reluctance motor as an example, he carefully evaluates the sensitivity that parameters specific to topology optimization have on the results.

Furthermore, the effects of the Gabor filter, the latest option for topology optimization available from JMAG V22.2, are also shown.

For those who are just starting out with topology optimization, we strongly recommend that you attend this lecture, as it will serve as a model.

12/6 17:30-18:00

Concept design session: Mr. Yushi Kido, AISIN CORPORATION

Topology Optimization of SynRM Using Gabor Filter

2023-11-17Masahiko Miwa

Topology optimization calculations are easy to use because there is no need to impose detailed shape constraints in advance.

Topology optimization calculations are easy to use because there is no need to impose detailed shape constraints in advance.

However, the high degree of freedom in shape may result in shapes that are difficult to manufacture.

Therefore, hybrid optimization calculations are attracting attention, in which topology optimization calculations are applied to parts where degrees of freedom are desired, and shape parametric optimization calculations are applied to parts where topology is fixed considering manufacturability. .

In this lecture, we will discuss the latest hybrid optimization calculations and their product applications.

It is demonstrated that hybrid optimization calculations not only provide realistic optimal shapes, but also provide better optimal solutions than shape parametric optimization calculations alone.

After attending this lecture, you will definitely want to try hybrid optimization.

12/6 17:00-17:30

Concept design session: Mr. Kazuki Sato, OMRON Corporation

Hybrid Method of Topology and Parameter Optimization Considering Magnetic and Circuit Properties of Power Electronic Devices -The Application Example to Wireless Power Transfer-

2023-11-17Masahiko Miwa

“I thought the basic design was OK, but in the detailed design I realized that I couldn’t meet the heat and strength requirements, so I had to start over from the basic design again…Damn…” For those who have had such a bitter experience

“I thought the basic design was OK, but in the detailed design I realized that I couldn’t meet the heat and strength requirements, so I had to start over from the basic design again…Damn…” For those who have had such a bitter experience

. Isn’t there a lot?

If we had been able to do not only the magnetic circuit design but also a simple thermal design and strength design at the basic design stage, we might have been able to proceed smoothly to detailed design and actual equipment evaluation without having to rework.

JMAG-Express is a tool that multifacetedly evaluates various physical phenomena such as magnetism + heat + structure + electric field at the basic design stage of a motor.

The latest version of JMAG-Express allows users to easily register their own rotor and stator shapes and evaluation details (scenarios).

In this lecture, he will introduce an example of using the custom functions of JMAG-Express to evaluate not only the magnetic circuit of a user’s own motor considering PWM current, but also the heat and strength at the same time.

Furthermore, optimization calculations were performed using JMAG-Express.

This is a must-see lecture for anyone who has had a bad experience with reworking a design.

12/6 14:00-14:30

Concept design session: Mr. Takeshi Hara, YANMAR HOLDINGS CO.,LTD.

Magnetic, Thermal and Vibration Evaluation of Permanent Magnet Synchronous Motor Considering High Frequency Component of Electric Current by PWM

2023-11-17Masahiko Miwa

: Taisan Industrial Co., Ltd.

The current design and development process for electromagnetic pumps has several challenges, including the number of prototypes produced and the sharing and accumulation of design data.

The current design and development process for electromagnetic pumps has several challenges, including the number of prototypes produced and the sharing and accumulation of design data.

By introducing JMAG, we aim to resolve these issues.

As a first step, we needed to confirm how well the experimental and analytical results matched.

In the lecture, we will present our achievements so far and future challenges.

We especially welcome those who are thinking about introducing JMAG from now on, or those who have already introduced it but are wondering how to utilize it in their development process.

The introductory session is aimed at companies that have never presented at a JMAG user meeting.

We hope that you will be able to empathize with the hardships faced by those who have changed from a world without JMAG to a world with JMAG, and that this will be an opportunity for you to expand your scope of use.

12/7 9:00-9:30

Introduction session: Mr. Taisuke Miyazono, Taisan Industrial Co., Ltd.

Implementing JMAG into the Design and Development Process and the Challenges Involved

2023-11-16Takashi Fukuoka

The JMAG User Conference will start in the United States, then travel to India, Taiwan, South Korea, Germany, and China, with a final stop in Japan in December.

The JMAG User Conference will start in the United States, then travel to India, Taiwan, South Korea, Germany, and China, with a final stop in Japan in December.

We held venues in all countries and had more customers participate than before the coronavirus.

There was a lively exchange of opinions on what should be done to develop good products, regardless of company or industry. At the end of the meeting, we were told that we had gained new knowledge, which made us even more happy.

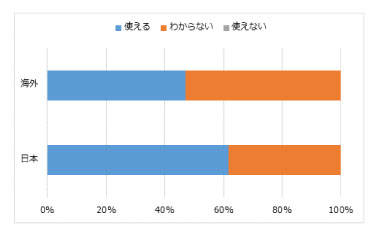

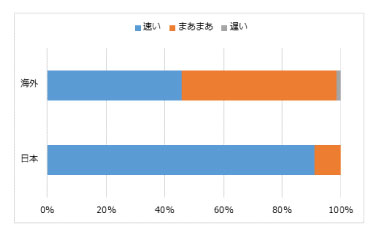

Well, at this year’s user meeting, we conducted a unified questionnaire about the new JMAG-Express, and received responses from over 200 people.

In Japan, I will be a JMAG-Express seminar participant.

It’s hard to say for certain because it depends on the tools you’ve been using, but

the trend seems to be that people overseas don’t find JMAG-Express to be that fast.

Or maybe Japan just paid lip service to it.

At the user meeting in December, we will ask everyone to evaluate the upgraded JMAG-Express.

I’m half anxious and half excited to see if people will find it useful and want to use it more.

Programs of JMAG user groups in each country

- June in USA

- July in India

- September in Taiwan

- September in Korea

- October in Germany

- November in China

2023-11-15Marketing team

This session is planned as a time for communication between student participants and between JMAG and students.

This session is planned as a time for communication between student participants and between JMAG and students.

There will also be poster presentations from 15 students. The number of poster presenters is increasing every year, which makes us very happy.

We hope that this will be a good opportunity for students to interact with each other about their daily interests, questions, and research topics.

■Academia session overview

– Lunch time session: 12/6 (Wed) 12:20-14:00 (1st day only)

– Student poster: 12/6 (Wed) 15:30-17:00 and 12/7 ( Thursday) 14:40-16:10

– Social gathering: 12/6 (Wed) 18:30-20:00 (1st day only)

https://www.jmag-international.com/jp/conference2023/academia-session/

During lunch time on the first day, we will introduce our efforts to develop motors for electric vehicles so that you can get a feel for our electrification efforts through JMAG.

A motor design seminar for students was held on October 2023.

When I spoke with the students who participated, I

learned that although they were deeply knowledgeable about the technology related to their respective research themes, they were eager for information on the background and market.

Therefore, we have decided to organize the academia session into two parts: a lunchtime session where students can get a broader perspective, and an evening session where students can explore technology through poster presentations.

Currently, we are checking reports and analyzing them based on questionnaires received from JMAG users so that we can introduce the electric vehicle market and surrounding environment to students in a short period of time .

It is full of information that can only be found here.

Please look forward to it

Murei will provide explanations and demonstrations.

We look forward to your participation!

2023-11-14Kyoko Sasaki

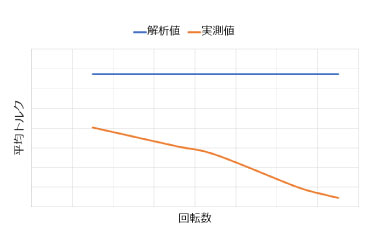

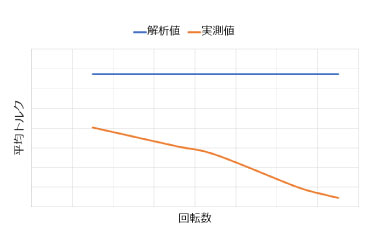

Actually, a while ago we received inquiries from several customers that the average torque did not match the actual measurement. When simulating the JMAG-RT model in combination with the control circuit, there are errors from actual measurements. On the other hand, when the IT (current-torque) characteristics were evaluated using the same model, they matched well with actual measurements. Is there an error between JMAG-RT and JMAG-FEA under certain driving conditions? I thought so, but I didn’t know the cause.

Actually, a while ago we received inquiries from several customers that the average torque did not match the actual measurement. When simulating the JMAG-RT model in combination with the control circuit, there are errors from actual measurements. On the other hand, when the IT (current-torque) characteristics were evaluated using the same model, they matched well with actual measurements. Is there an error between JMAG-RT and JMAG-FEA under certain driving conditions? I thought so, but I didn’t know the cause.

Have you encountered anything like the above in your communication with Professor Takemoto of Okayama University, who will be giving a lecture this time? When I asked about this, I was told that Professor Takemoto had indeed received similar inquiries. Because of this, we decided to take up this theme as part of the V&V (Verification & Validation) project, and we decided to ask Professor Takemoto for his cooperation.

As I analyzed various aspects of the project in detail, I realized that it was a very interesting but difficult problem. It is not clear from the actual torque data alone, and we have learned that it is necessary to carefully look at the information from the angle sensor as well, and that the error varies depending on the driving conditions, such as being large or negligible. Ta.

In this lecture, Professor Takemoto will share with everyone the status of his studies so far. Please let me borrow your wisdom.

12/7 11:50-12:20

Special Speech: Dr. Masatsugu Takemoto, Okayama University

Investigation of Error Factors between Measurement and Analysis Results of Torque in a Permanent Magnet Synchronous Motor under High Speed Rotation

2023-11-13Yusaku Suzuki

Early registration benefits will be available until tomorrow, November 14th.

Early registration benefits will be available until tomorrow, November 14th.

What are the benefits of applying early?

The first is priority participation in optimization theory courses. 12/6 15:40-16:50

We will explain the basics of how to use objective functions and constraints, and how they are handled internally depending on the settings.

This is a must-read for those who are starting to work on multi-optimization and want to organize their theory.

The second is to participate in intensive sessions. (Twice a day, four times over two days)

At the JMAG User Meeting, JSOL is planning a total of 16 seminars, 46 posters, and 7 basic courses.

Since the implementation is done in parallel, no one can go through everything.

Also, although we ask everyone to “please feel free to ask us any questions,” some people may not be comfortable asking us.

If you are shy or not sure which seminars or posters to attend, please join us for this intensive session.

Engineers will provide explanations for each theme.

- Motor design using JMAG-Express

- Modeling technology for high-precision analysis

- Analysis technology related to induction heating

Please apply as soon as possible.

2023-11-13Marketing team

The exhibition booth at this year’s JMAG User Conference is also something different.

The exhibition booth at this year’s JMAG User Conference is also something different.

We would like to introduce four new exhibitors.

The first exhibitor application was Nagaoka Motor Development Co., Ltd.

In addition to prototyping and designing motors, we are happy to provide consultation to anyone who has problems with simulation model creation, control software creation, drive circuits, etc.

China-based Qingdao Yunlu Advanced Materials Technology Co., Ltd. will also be participating this year. Yunlu’s materials will also be included in the JMAG V23 material database, so be sure to check out our new partners.

Chuo Zuken Co., Ltd. would like to introduce KULI.

They will be able to introduce a solution that evaluates the designed motor in terms of vehicle electricity consumption performance.

In addition, Powersys will introduce a powertrain design optimization solution that links SIMBA and JMAG-RT, which are simulations for power electronics.

In addition, all 21 exhibiting companies, including measurement manufacturers, are preparing for this day.

https://www.jmag-international.com/conference2023/event/

look forward to it.

Academia session:

Poster presentations by students that were popular last year. This year, he will present to 15 students over two days.

https://www.jmag-international.com/conference2023/academia/

the presentations look interesting. Businesses and students are welcome to have a discussion with the students at the venue.

There will also be a lunchtime session exclusively for students that introduces efforts to develop motors for electric vehicles.

I would like to be able to talk with other students about initiatives at other universities.

Connect with many people through JMAG.

2023-11-10Marketing team

JMAG turns 40 this year. This will be the 30th user meeting.

JMAG turns 40 this year. This will be the 30th user meeting.

We are very happy to be able to welcome so many customers in this commemorative year.

In addition, the user meeting preparation diary that is distributed every day has been restored to its pre-corona state.

Today, I would like to briefly introduce the content that is being prepared by the JMAG User Group.

After that, we will update you on the preparation status on a daily basis.

In this preparation diary, I would like to introduce information that has not yet been posted on the website.

The theme of this year’s JMAG User Conference is “The Great Potential of Simulation Technology,” and we have prepared various contents.

JSOL lecture

We will introduce the product vision and development plan in two parts.

Please check it out to see if it fits your plans.

Keynote Speeches and User Presentations

Optimization is used in many of the presentations, and it seems that there is a shift from trying to reduce the amount of calculations to how to maximize the amount of calculations.

You say it doesn’t matter to your company because you only use basic functions! ! Seeing is believing.

Please come and gain new insights from the lecture.

Seminars and Posters

Another feature of the JMAG User Group is that we provide time for communication twice a day.

This year, we are preparing 15 seminars and 46 posters.

In the past, we have received feedback from people who do not know how to operate JMAG even though it is introduced in posters.

Therefore, we will also prepare an environment where you can conduct a demonstration linked to the poster. We call it a moving poster.

It appears once a day, and the same theme never appears twice. Please join us throughout the two days.

Keywords:

Detailed explanation of JMAG-Express / High-precision large-scale calculation / Multi-objective/multi-constraint optimization / Efficiency map / Topology optimization / Utilization of surrogate models / NVH / Thermal evaluation / Control coupling / Material modeling (magnets, steel plates, Iron loss) / JMAG-RT / Induction heating / Non-contact power transfer / Resolver / Linear motor / Transformer / Reactor converter / Simulation accuracy verification

*For those who apply by November 14th and are interested, we will also provide intensive explanations for each theme.

Please feel free to join us.

– Motor design using JMAG-Express

– Modeling technology for high-precision analysis

– Analysis technology related to induction heating

JMAG History Board (Permanent Exhibition)

A summary of JMAG’s added functions to date.

I would like to look back on the past 40 years and talk about the future with everyone in front of this panel.

There are many other plans including student sessions, partner seminars, and workshops.

Please look forward to the preparation diary from tomorrow.

2023-11-09Marketing team