Kohei Matsuura

Design Section Rotating Machinery Department 1,

Rotating Machinery Systems Division,

TMEIC Corporation

Abstract

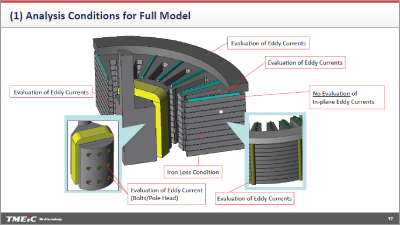

Oil and gas plants as well as steel mills have broad demand for large capacity TMEIC synchronous motors for use in industrial compressors, pumps, and other such applications. In recent years, CO2 emission and running costs reductions are driving the need for even greater efficiency against a background of environmental problem and rising energy costs. In order to evaluate motor efficiency, prototypes of these motors is difficult because the production costs of large capacity machines over 10,000 kW are veryhigh. Finite element analysis provides a highly accurate solution to estimate the losses. This case study divides one electric motor into several models and runs three-dimensional analyses to obtain the losses produced in each part for a comparison against actual measurements. These analyses do take more time to evaluate the large-scale models necessary to simulate such a sizable machine, but this case study takes advantage of Massively Parallel Processing (MPP) to report on the effective reductions in the time required to run the analyses.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in