JMAG-Express

JMAG-Express quickly performs multifaceted evaluation to obtain machine design that meets performance requirements.

Operations are easy with templates for motor geometry and evaluation results. The templates can be reused and you can run multipurpose optimization with the built-in engine.

Design exploration covers magnetic, thermal, structural, and control design and tests a wide range at high speed from concept design to detailed design.

JMAG-Express

- One-click simultaneous evaluation of magnetic, thermal, and structural characteristics of motors

- High-speed calculation makes way for evaluation of multiple motor designs

- Run a detailed evaluation in JMAG-Designer by just switching display mode

- Flexible support for analysis accuracy requirements and various applications

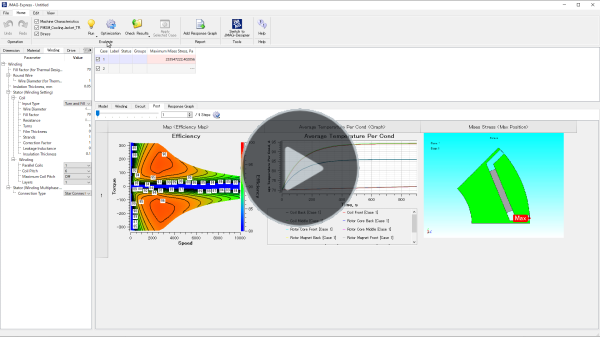

Multi-disciplinary evaluation of motors using JMAG-Express

Enter motor specifications and run to view magnetic, structural and thermal motor performance. Check the efficiency map, history of parts temperature, and where the maximum stress originated and its value. In addition, you can view a comparison of multiple design plans in a single screen.

Capabilities

- Motor design

- Customization of motor type and evaluation items

- Parametric studies that cover magnetic, thermal, structural, and control design

- Design exploration using the built-in optimization engine

- More comprehensive and flexible analyses by adding evaluation items or switching to JMAG-Designer

- Control/NVH evaluations via links to third-party tools

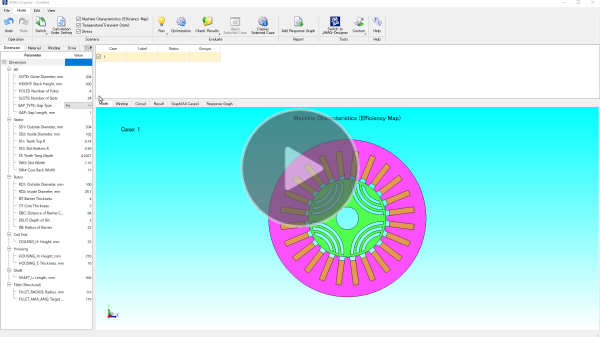

Motor design

JMAG-Express can evaluate designs based on templates for motor types from PMSM and induction motors to EESM, WFSM, and SynRM. A combination of multiple scenarios preinstalled with JMAG-Express even enables fast evaluations of various design ideas that satisfy not only the magnetic but also thermal and stress requirements.

- Magnetic design: machine constant, efficiency map, cogging torque, torque ripple, induced voltage, demagnetization

- Thermal design: natural/forced cooling, cooling jacket, temperature evaluation in a drive cycle, etc.

- Structural design: stress evaluation

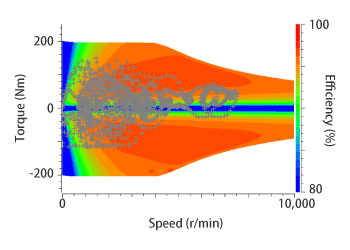

Efficiency map and operating points for driving mode

Efficiency map and operating points for driving mode

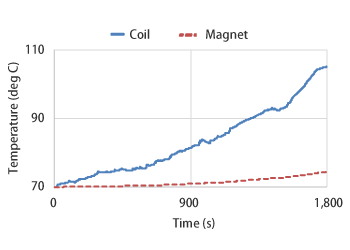

Time history of temperature

Time history of temperature

Create efficiency maps quickly. During WLTC mode drive, you can also check the efficiency, loss, and more. These loss histories can then be referenced in thermal design, and the temperature history of the parts can be evaluated. After running WLTC mode drive, the magnet and coil temperatures have increased by 5 deg C and 35 deg C, respectively.

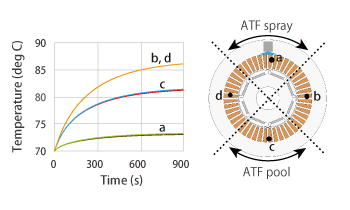

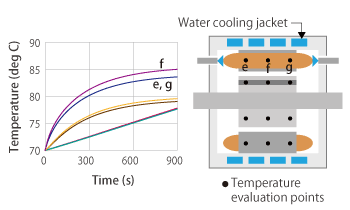

Thermal circuit models are available for general cooling types for motors. Multiple temperature evaluation points are established in the axial and circumferential directions in addition to the temperatures for each part. Temperature evaluation is then run accounting for the deviations in cooling that occur as a result of each cooling type.

From the graph, it can be seen that temperatures are higher at the coil ends where the ATF spray is not directly applied, as well as the middle of the coil. This occurs even within the same coil.

JMAG Function Videos

Customization of motor type and evaluation items

You can register your own custom templates for geometry and evaluation items not available out-of-the-box in JMAG-Express to delve deeper into designs.

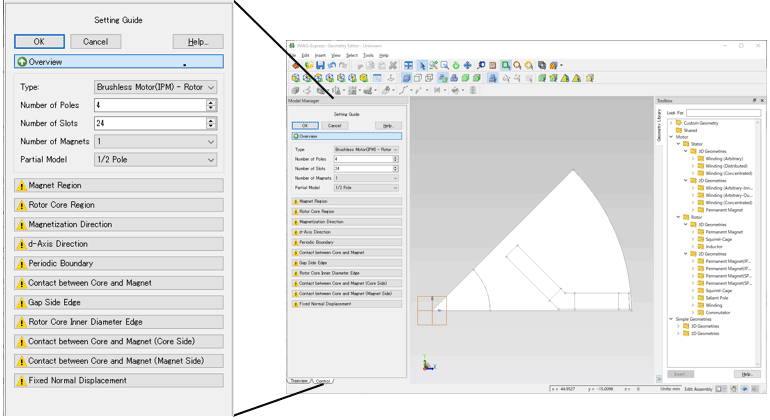

Anyone can simply follow the setup guide to easily customize and register new motor geometry as a user template. Combine machine characteristic, thermal, and structural evaluation scenarios that come with JMAG-Express with these user templates to evaluate your own motor geometry.

These scenarios act as a template encompassing the analysis method, materials, analysis conditions, mesh parameters, electric, thermal, and control circuit as well as other basic FEM analysis settings. Customization allows users to register and add new scenarios tailored to their specific needs.

Setting guide panel in the Geometry editor

Setting guide panel in the Geometry editor

Load the DXF file and follow the setting guide. The geometry can be registered as a geometry template as it is and can be used in JMAG-Express for machine characteristics, temperature, and stress scenarios evaluations.

JMAG Function Videos

Parametric studies that cover magnetic, thermal, structural, and control design

Combine any design variables to test various design plans.

The JMAG-Express license can simultaneously run multiple designs.

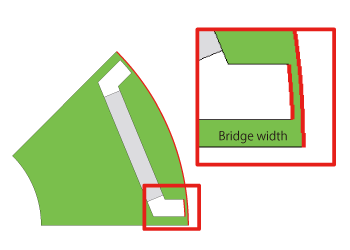

Rotor shape and design variable

Rotor shape and design variable

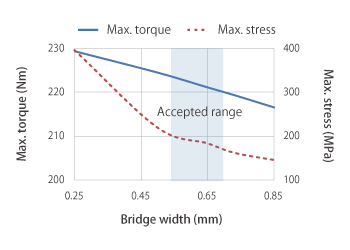

Bridge width, maximum torque and stress

Bridge width, maximum torque and stress

Evaluated maximum torque and maximum stress with design variable of the bridge width. When making bridge width wider, stress decreases but the maximum torque is also decreased. Both requirements of torque and stress are fulfilled around 0.65mm.

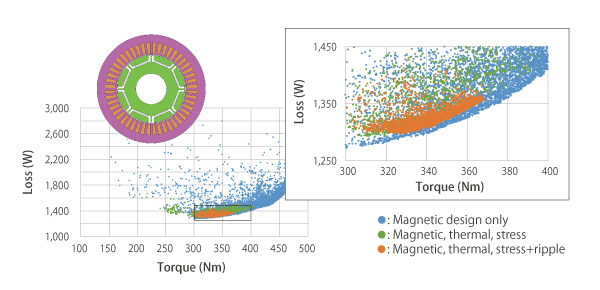

Design exploration using the built-in optimization engine

Supports parametric optimization.

You can combine parameters such as magnetic, thermal, structural, and control design to run multipurpose optimization

A comprehensive search can be performed in the early stages of design.

9 geometry dimensions are the variables for an 8-pole, 48-slot IPM motor. Parameter optimization is run with average torque maximization, torque ripple minimization, and loss minimization as the objective functions. By accounting for not only magnetic characteristics as a constraint condition in the early stages of design but also design requirements such as thermal, stress, and ripple, even more appropriate design plans can be narrowed down even faster.

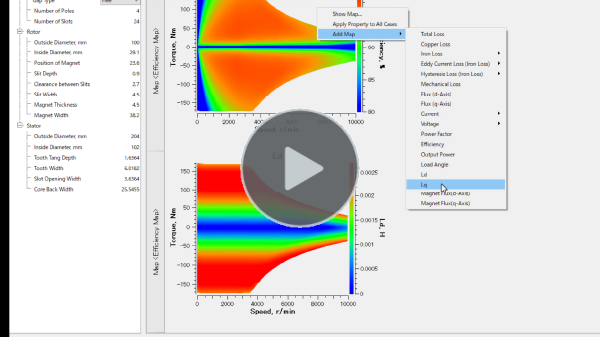

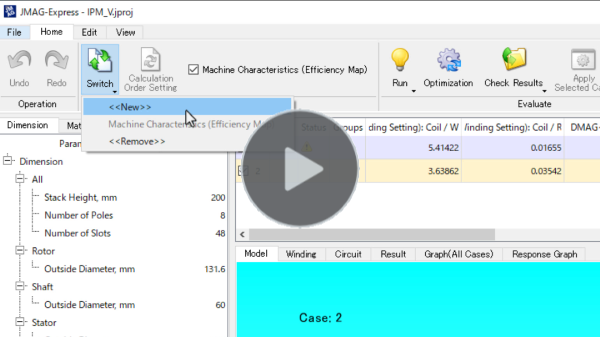

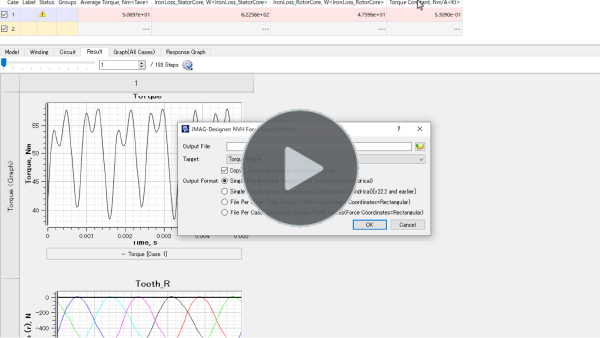

More comprehensive and flexible analyses by adding evaluation items or switching to JMAG-Designer

JMAG-Express and JMAG-Designer always share all settings including model and condition settings.

You can easily go back and forth between JMAG-Express and JMAG-Designer by switching views and running a detailed evaluation in JMAG-Designer.

JMAG-Express can carry over existing cases and add torque ripple scenarios and other evaluation items to after running machine characteristics (efficiency maps), cooling, and other scenarios for even more comprehensive evaluations.

JMAG Function Videos

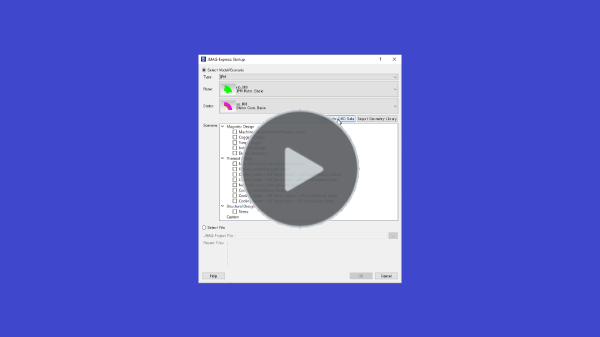

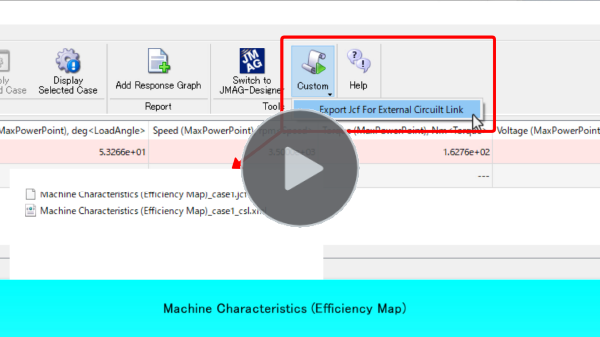

Control/NVH evaluations via links to third-party tools

JMAG-Express can export the model data necessary to run control/circuit simulations and the electromagnetic data required to evaluate NVH with one click.

Magnetic designers can work in tandem on motor designs with teams handling the control design and NVH issues to create designs that integrate the entire system at the earliest possible stage of the design process.

JMAG Function Videos

Application Catalog

please contact us.

![[JFT185] The Use of Custom Geometry in JMAG-Express (Ver.23.0 or Later)](/wp-content/uploads/common/bn_ft-150x150.png)

![[JAC290] Design Exploration of IPM Motors, Including Evaluating Part Temperature, Stress, and the Presence of Electric Breakdown](/wp-content/uploads/catalog/jac290-1-150x150.png)