This email provides you with the most up-to-date information on JMAG!

Recommended Leaflet:

[L-OP-190] Standalone Simulations to Evaluate Magnetic, Thermal, Structural, and Control Designs

Drive motors for electric vehicles need to not only meet high power density, high torque, high efficiency, and other performance requirements but also must minimize vibrations and noise, maintain mechanical strength at high speeds, suppress heat under high loads, and lower costs. Designers generally evaluate performance requirements primarily through the magnetic design. However, insufficient mechanical strength or excessive heat can force engineers to rework the magnetic design later on in development, which is a massive undertaking. The significant safety margin often left to avoid this rework inevitably drives up costs.

A comprehensive development process that refines the thermal, structural and control designs alongside the magnetic design can attain the necessary performance, strength and heat management. A standalone simulation-based design workflow takes every design into account to automatically obtain optimal design solutions that satisfy all requirements while reducing the risk of any rework.

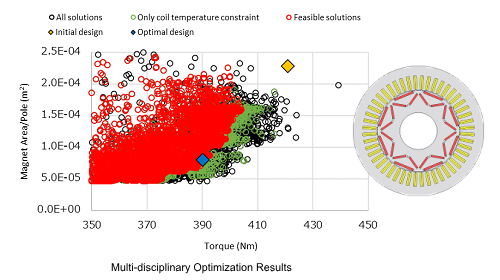

This case study runs an optimization on the initial nabla-shaped IPM drive motor design to maximize torque and minimize magnet mass for greater fuel economy during the WLTC drive cycle. The simulation also limits magnet and coil temperatures as well as stress at high speeds. The results show that design solutions with the highest torque exceed temperature and torque tolerances. This demonstrates the necessity of multi-disciplinary evaluations in finding optimal design solutions without any rework.

To read more, please see the following page!