Mayu Maruyama

MG Design Section, Engineering Department 1,

Power Supply Technology Co., Ltd. (Abbreviated: PST)

Abstract

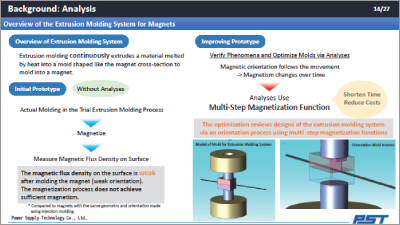

In the process of magnet extrusion molding, the extruded material is anisotropic and oriented to concentrate the resulting magnetic flux in a desired direction during the magnetization stage. However, the resulting surface magnetic flux density after molding is weak and sufficient magnetization is not achieved. Since magnetic field orientation varies as the piece is extruded, its magnetization state changes over time. Such a phenomenon needs to be accounted for and can be treated by the multi-step magnetization function. In this presentation, we will report on the design optimization of an extrusion molding system including the effect of motion with the multi-step magnetization function.

Power Supply Technology Co., Ltd.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in