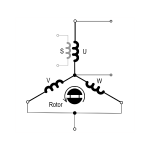

Fig. 1

Alexanderson alternators had these design parameters:1

| Power output | 10−200 kW |

| Frequency | 10−100 kHz |

| Configuration | Axial-flux inductor alternator |

| Permanent magnets | None |

| Application | Long-distance wireless communication |

Electric machine designers will surely look on these figures with admiration—even with astonishment—given that the era of the Alexanderson alternator (including its antecedents) was from about 1900 to about 1930.2

But why should we be interested in it today? The famous quote of Henry Ford comes to mind, often given as “History is bunk”. The full record of Henry Ford’s argument is not so damning to our engineering forebears.3 He said that we should be making history today—and we are most definitely doing that with our EVs and power electronics and finite-element methods! So why would we be interested in Alexanderson’s alternator?

I would suggest two reasons. First, engineering history is fascinating in itself: rich in examples of human ingenuity, with insights into the very process of invention. More specifically, we can often find the express reasons why things were done the way they were done. Of special interest to us today are several features of modern products that we take for granted, unaware of the original reasons for them. In many cases the designer’s logic has been inherited through generations of textbooks and college courses, which have gradually lost sight of the original thinking. (This is true in mathematics as well as in engineering).

The second reason is also an educational one. The Alexanderson alternator would be a good topic for a student project, especially a group project at the advanced undergraduate or master’s level. Think of the model EV that is so popular in students’ group projects (with races at the end of the session!). They have a wealth of engineering aspects and disciplines; they are modern; and they are exciting and relevant—great characteristics for young engineers to experience in training. The Alexanderson alternator has all of them. It could be argued that it is obsolete and has no practical application, but that’s not the point: it has many features that can be found in modern machines, and it extends the design space beyond almost anything we see in current products.

Let’s review some of the technical features that might make for an interesting and educational project.

1. An axial-flux machine. Axial-flux machines have aroused much interest recently in relation to their power density, efficiency, and form. All of these aspects carry a high premium in modern applications, and the achievement of a satisfactory compromise has produced some outstanding examples of advanced numerical analysis (both electromagnetic and mechanical), together with the application of advanced materials and manufacturing processes. A modern equivalent of the Alexanderson alternator would have all these factors. In particular, the electromagnetic design calculations must be done in 3D to have any chance of being accurate, and that makes finite-element analysis highly desirable if not essential.4

2. High frequency (1). Electric machines generally do not operate at frequencies at the level of 100 kHz. Although it is well known that the size and weight of transformers decreases in inverse proportion to frequency, the operating frequency of rotating machines depends on the product of speed and pole-number. Faced with a demand for a 100-kHz machine, the designer has to choose both a high pole-number and high speed: for example, 600 poles at 20,000 rpm. It is not simply a question of the machine itself: the drive must be considered too. Alexanderson used both belt drives and speed-increasing gearboxes. At the speeds required for this application, detailed consideration must be given to the shaft dynamics (critical speeds); mechanical strength of components subect to centrifugal loading; and core loss and windage loss. Alexanderson coped successfully with all these challenges, more than a century ago.

3. High frequency (2). Alexanderson used a laminated core of thin electrical steel, the best available at the time. Although its magnetic performance was reduced compared with low-frequency conditions, and although there were significant core losses, the steel core was preferred over the purely air-cored configuration that was thought by some distinguished contemporaries to be more practical at the time. The flux-densities were necessarily lower (but not absurdly lower) than what we might expect to find today in high-speed machines, even those operating at high power-density. What would be interesting today would be to construct the stator core with compressed powder-core material (see Höganäs / Somaloy®)5 which would seem to be ideally suited. Or the very latest laminated electrical steel, which has been developed far beyond what was available to Alexanderson.

4. No magnets. The modern engineer might be forgiven for thinking of permanent magnets as the natural choice of excitation for a high-speed 100-kHz machine. Not so. In any alternator there is a need to control the output (in particular, the generated voltage, the power, and the power-factor), and the natural basis for this is electrical excitation with a field winding and a controlled DC current. Another important advantage of the wound-field machine is that the excitation can be switched off in the event of a short-circuit fault—extremely important in the case of a high-speed machine. If the application requires intermittent operation (as in Alexanderson’s radio-transmitter), a field winding is advantageous, especially because of its low power level, in contrast with the fully rated control electronics that would be needed in the armature circuit. With magnets the no-load losses would be a persistent headache at such high frequency. Intermittent operation with a low duty-cycle would be an advantage in an undergraduate project, because the machine could be operated with a flywheel and a low-power mechanical drive, without sacrificing any of the technological features on the electrical side.

5. Control aspects. Alexanderson had to control the speed of his alternator very accurately, because it determined the output frequency. The Grimeton radio station6 in south-west Sweden has produced some You-Tube videos which show this in exquisite detail. It uses a magnetic amplifier to control the speed of a wound-rotor induction motor driving the alternator through a speed-increasing gearbox, and you can see the frequency on a large modern digital frequency-meter with extraordinary stability.7 Nowadays, highly accurate speed control is almost taken for granted with field-oriented control and high-performance speed transducers, so an undergraduate project would not need to use a magnetic amplifier or a heavy liquid resistor (although those would also make interesting undergraduate projects in themselves!)

6. Loading. The electrical characteristics are always of vital importance in alternator applications, and the load on Alexanderson’s alternator was a very large radio antenna, to which it was tuned by means of variable inductors. We can see this huge structure at the Grimeton site today6. I found this especially exciting because it reminded me of a crystal set which my uncle made for me when I was a small boy, complete with a 200-ft wire aerial from my bedroom window to a poplar tree at the bottom of the garden. It used war-surplus headphones and it really worked. Later (in my grandmother’s kitchen) we made superheterodyne receivers with electronic valves (“tubes” in U.S. English), and there are today radio amateurs who keep the same technology alive and pride themselves on receiving the transmissions from Grimeton SAQ on the special days of transmission. So when we talk about the loading of alternators, don’t let’s forget these thrilling examples! There is more to it than wind turbines, wave-power, regenerative braking, and all the “serious” stuff.

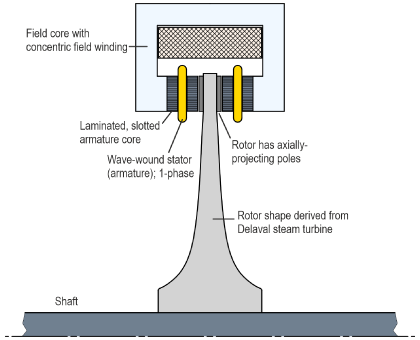

7. Materials. We have already contemplated the use of compressed powder-core magnetic material for the stator core, but what about the rotor? Alexanderson used a rotor shape derived from a Delaval steam turbine which solved related issues with centrifugal strength and rotor dynamics; but what about carbon-fibre composites?

8. Design method. Alexanderson published relatively little on the alternator.9 According to James Brittain,7 some of his papers are lodged at the Schaffer Library at Union College in Schenectady N.Y., and one would expect these papers to include hand-written notes and calculations. But it is almost certain that even if his original design calculations could be reproduced, the modern engineer would be frustrated by their ‘unknowns’ in areas such as material properties, electromagnetic field analysis, and core-loss data among many others. What would certainly emerge from a study of Alexanderson’s papers would be evidence of extraordinary mastery of experimental R&D coupled with a deep-seated appreciation of fundamental principles, driven by great technical courage and loads of hard work. We can see this in many kindred biographies, such as those of Steinmetz or Kelvin.10,11. But Henry Ford was right: those are not the prime sources for modern engineering. Our undergraduate project must be an original one, starting with some sketches and discussions, and moving steadily towards CAD drawings and finite-element models (covering electromagnetic, mechanical, thermal, control, and electrical-system aspects—just as in any modern real-life engineering project). It must also research the properties of suitable available materials. Even today, the behaviour of magnetic materials at 100 kHz is not a simple matter.

I would like to finish this Diary with a shout-out to the Alexanderson SAQ society at Grimeton in Sweden. If you don’t have a VLF superhet receiver tuned to 17.5 kHz, you can still find them on You-Tube and Wikipedia. And if you listen to that transmission you’ll be connected all the way back to Maxwell. The only thing that’s missing is a finite-element analysis of Alexanderson’s alternator! Maybe a bright student will produce one, and maybe a bright group of students will actually make one!

Notes

1 Several different ratings and frequencies were used in different installations and at different stages of development. The figures in the table are typical of published values. The highest frequencies were not generally achieved at the highest power ratings.

2 A few Alexanderson alternators were in regular use up to and beyond the Second World War. According to Williams12, two Alexanderson alternators each rated 200 kW were installed in 1920 in North Wales. They were first used on 24 April 1921 transmitting at 21.4 kHz and 31.25 kHz respectively with an aerial current of 330 A. For some time this was the most important transmitting station in Britain. Some excellent black-and-white photographs of this facility (from 1912 onwards) together with details of earlier and later technological developments are given in 12.

3 https://www.hemmings.com/stories/fact check what henry ford meant when he said history is bunk/

4 The axial-flux machine does not have the highly developed analytical theory or design procedures available for cylindrical-rotor machines. That is partly due to its relative rarity, but it is also not amenable to approximate 2D geometric models.

5 https://www.hoganas.com/en/powder technologies/soft magnetic composites/… Interestingly, Höganäs is not far from Varberg on the S.W. coast of Sweden, the location of the Grimeton radio station SAQ which operates a fully-configured historic transmitting station with an Alexanderson alternator to this day.6

6 https://en.wikipedia.org/wiki/Grimeton_Radio_Station

7 See the excellent biography by James A. Brittain, Alexanderson, Pioneer in American Electrical Engineering, The Johns Hopkins University Press, 1992. ISBN 0-8018-4228-X. The magnetic amplifier was another of Alexanderson’s many significant inventions.

8 U.S. Patent 1008577, High Frequency Alternator, November 1911.

9 E.F.W. Alexanderson, Alternator for one hundred thousand cycles, Transactions A.I.E.E., June 1928, 1909, pp. 399-412

10 Ronald R. Kline, Steinmetz, The Johns Hopkins University Press, 1992. ISBN 0-8018-4298-0

11 David Lindley, Degrees Kelvin, a Tale of Genius, Invention, and Tragedy, Joseph Henry Press, Washington D.C., 2004. ISBN 0-309-09073-3

12 H. Williams, Marconi And His Wireless Stations in Wales, Gwasg Carreg Gwalch, 1999. ISBN 0-86381-536-7. (110 pages)

13 Elmer E. Bucher, Technical Description of The Alexanderson System for Radio Telegraph and Radio Telephone Transmission, Wireless Press / Radio Corporation of America, New York, 1920