Overview

By prototyping and testing motors, design problems can be identified and rework in the mass production stage can be reduced. However, prototyping is costly and time consuming. The solution to this problem is virtual prototyping, in which simulations are performed on a computer and the product is designed without prototyping.

JMAG models the actual machine as it is, and by visualizing physical phenomena that are normally invisible to the eye, it is possible to immediately confirm information beyond what can be obtained from the prototype. In this case, invisible losses were confirmed at the operating point in the high-speed range (12,000 rpm), where phenomena are complicated by weak field magnetization and high frequencies, etc., for the drive motor.

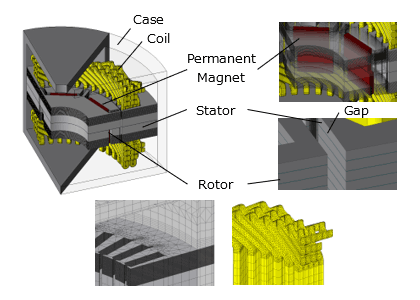

Fig.1 Detailed modeling based on actual machine

The magnet with step skew, coil ends, case, and laminated steel sheets are precisely reproduced. Air gaps are provided between the laminated steel sheets, and a skin mesh is generated for the coil and case. The number of elements is 3.3 million and the number of steps in one electric angle cycle is 438.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in