Elaborate Modeling Technology

Modeling Complex Nonlinear Materials at a Micro Level

\( \Large \nabla \times \frac{ l }{\mu_0}\nabla \times A = J -\sigma \frac{ \partial A } { \partial t } \nabla \times M \)

The equation indicated above is the same basic magnetic field analysis equation that can be found in text books. Despite the simplicity, this equation indicates a elaborate distribution for materials because electric conductivity, σ, and magnetization, M, have nonlinear characteristics. These characteristics complicate physical phenomena while drastically affecting the performance of an electrical device. The material modeling used to simulate complicated material properties has a crucial role in simulation technology.

Modeling microscopic nonlinear material properties was achieved through years of cumulative experience. The magnetizing properties of nonlinear materials can be calculated using the Newton-Raphson method by specifying a point sequence for the BH curve. An optimal model for an iron loss analysis is also available using the Steinmetz empirical formula. However, materials have to be modeled very accurately for a limit design that aims to miniaturize a device while increasing efficiency.

Accurate Modeling and Powerful Analysis Capabilities required for Limited Design

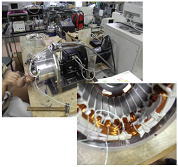

Motors used for various applications such as cars, require miniaturization while also demanding a reduction in cogging torque and losses. A simulation must obtain highly accurate results to correctly evaluate the miniscule differences in cogging torque. The noise canceling technology implemented in the mesh generation engine that was introduced in the pervious Technical Report can provide a highly accurate numerical analysis.

However, the analysis results and actual measurements will not match even with a highly accurate numerical analysis because the accuracy of the material properties that are modeled, such as anisotropic magnetic materials, affect a simulation more as the accuracy of an analysis increases. This means the materials need to be modeled more accurately for a limit design.

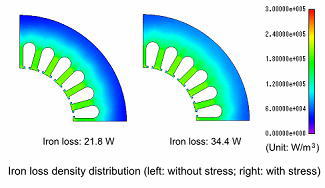

Material modeling requires a specific number of elements to simulate phenomena accurately, but there is another aspect to these “evaluation” tools. Performance characteristics can be obtained through measurements and experimentation, but effects of those characteristics, such as the effects of stress by shrink fitting on magnetic properties, cannot be obtained easily. However, simulation technology has come to be known as an essential tool for analyzing small but vital differences in material properties, providing engineers with the ability to distinguish these slight differences.

Evaluation capabilities by material modeling is crucial to finding solutions to problems. For example, a magnetization analysis can be performed when the properties of the magnet are inaccurate and the back EMF waveform is off. This type of material modeling is extremely accurate and indispensable when trying to solve analytical problems.

The effects of deterioration caused by stress cannot be visualized with measurements or experimentation.

The effects of deterioration caused by stress cannot be visualized with measurements or experimentation.

Integrated Modeling Tools for Analyses

It is difficult to cover the extensive range of material modeling in just a few words. However, the logic behind modeling materials can be viewed as:

Material modeling = material properties + composite materials + externalenvironment

The accuracy of the materials that are modeled cannot simply be thought of as improving the quality of the material properties, but rather modeling the material considering a wide range of variables from modeling composites, such as laminated steel sheets, to the effects of heat and stress. JMAG implements a variety of tools to cover the vast range of variables necessary to model materials accurately.

(1) Material Database with Expertise

JMAG implements a database of material properties that includes magnetic and loss characteristics provided by the material manufacturers.

JMAG’s material database has reliable data that is guaranteed by, and created with the mastery of the manufacturers. An irreversible demagnetization analysis can be performed using data for a magnet provided by Hitachi Metals, or the magnetic characteristics of the stress dependency of a material provided by Nippon Steel can be used. Each user can also model irreversible demagnetization or magnetic characteristics of the stress dependency in JMAG based on this know-how.

(2) Modeling Specific to Composite Materials

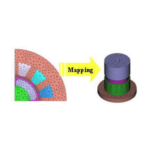

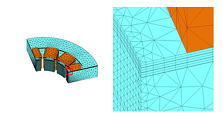

It is essential to model members of materials that have laminated steel sheets or are anisotropic accurately while selecting the appropriate method for modeling. For instance, mesh is not usually generated to model each steel sheet. Generally, the laminated steel sheets are modeled using a block and the analysis load is reduced by specifying the lamination factor. However, a mesh needs to be generated to model the lamination on the surface of a motor if the magnetic flux in the axial direction is strong, such as slim line motors. Tools to increase the accuracy of modeling by selecting the appropriate method based on the purpose of an analysis is said to be one of JMAG’s strengths.

(3) Accounting for External Environmental Effects using a Coupled Analysis

The material properties vary with stress and temperature. The temperature and stress dependency not only need to be determined to visualize these effects, but the temperature distribution and stress distribution also need to be obtained accurately. JMAG implements a coupled analysis function that can accurately evaluate the impact of the temperature and stress dependency. More information about the coupled analysis technology will be introduced in the next edition of the JMAG Newsletter.

“Powerful Modeling” Achieved Through Experience

The modeling tools generally used for analyses in JMAG have been introduced, but the larger question of how the various options are actually used has not been addressed.

The modeling technology in JMAG has been built on a foundation that is supported by experience that spans 30 years. The modeling tools are utilized capturing this expertise of the functions to increase the accuracy when modeling materials, or combining actual measurements into an analysis.

The JMAG analysis engineers have designed a process proven through actual measurements for developing valid and new methods for modeling.

The God of Design Resides in Detail

The essential aspects of design, such as limit based design, are hidden in the small but vital “differences” of the members of materials. JMAG offers modeling tools and powerful analysis functions that cast light on these minuscule differences.

JMAG will continue to strive to meet the challenges of modeling complicated materials.

Physical modeling such as coupled analyses will be introduced in the next edition of the JMAG Newsletter.

[JMAG Newsletter Winter, 2010]