Kim Bergsro

Electric Driveline,

Volvo Cars

Abstract

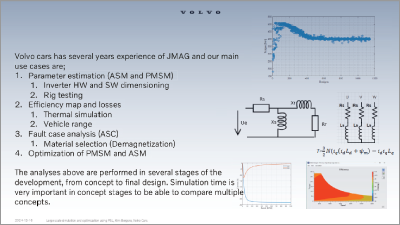

Volvo cars have for some years been working with inhouse development of electric machines and electromagnetic simulations. FEA simulations are time consuming and therefore the simulation time is something that is beneficial to reduce to save cost. This results in that each simulation is of importance in terms of result but also development cost, and you want to reach a final design as quickly as possible with the best accuracy.

The use of Direct optimization using multi-objective genetic algorithm often needs to solve many cases to converge to designs fulfilling the optimization targets. Depending on the number of objectives it is common to run 5000 – 10000 cases. This can take several hundreds of hours. We have successfully run large optimizations for PMSM machines using PSL where the time saving is hundred-fold when comparing to a small number of solvers which is normally needed to ensure the usage of JMAG designer within the design team.

To save cost and development time reducing the number of test objects and test time is desired, a good prediction of the electric machine losses is enabling this. The most accurate way to calculate the electric machine losses, especially in magnets and winding is to simulate a 3D model of the design. 3D modelling is quite resource intense due to the large mesh size needed and thus a high simulation capacity is needed.

The above topics can be enabled or improved by utilizing the PSL solution provided by JSOL for JMAG. The usage of PSL is enabling a faster time to final design but also making sure that calculation of an efficiency map for a 3D model can be performed within a reasonable time frame.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in