Masato Taira

Surface Treatment Process SectionⅡ, Process Technology Division, Research & Development,

NIPPON STEEL CORPORATION

Abstract

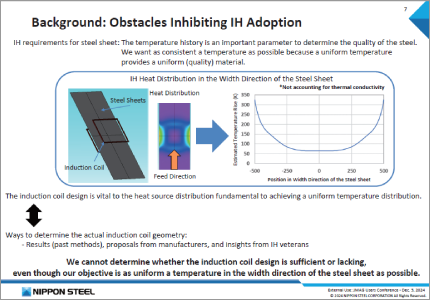

In steel industry, continuous processing lines are used to manufacture most of steel strips, which are thin steel sheets used in the production of automobile bodies and containers. In continuous processing line, steel strips are continuously conveyed, and heating, cooling, and other processes are carried out continuously to efficiently produce products. In the context of carbon neutral movement, the electrification (applying induction heating) of the heating process in the line is an option to be considered. Until now, induction coils for running strips have often been designed empirically and it has been difficult to tell whether the design is suitable. To investigate the possibility of a data-driven design, the shape of the induction coil was studied by topology optimization using the temperature distribution in the running strip width direction as the objective function.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in