Alireza Fatemi

Global Research & Development,

General Motors

Abstract

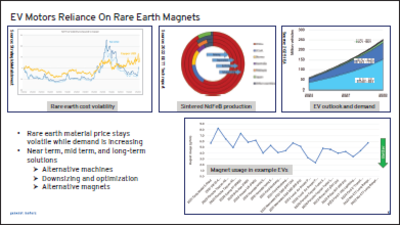

The performance and reliability of permanent magnet (PM) rotors are closely tied to their magnetic state throughout the product life cycle from initial post-assembly magnetization to field-induced demagnetization under demanding drive conditions. This presentation introduces a unified modeling framework that captures this entire spectrum. The study begins with finite-element simulations of post-assembly magnetization (PAM) in interior PM rotors, highlighting how magnet layout, V-angle, and local saturation distribution affect achievable remanence. It then extends to simulating progressive demagnetization under combined thermal, electrical, and magnetic stressors, validated by controlled rotor-level experiments. A simplified “rotorette-level” characterization platform, which isolates a single magnetic pole for high-fidelity flux and back-EMF correlation, is also discussed. By integrating magnetization and demagnetization analyses within a single digital workflow, this approach enables prediction of end-of-life PM properties and informs design choices for magnet grade, pole geometry, and excitation control. The results show that accurate modeling of PM magnetization and demagnetization can lead to cost savings through better magnet utilization and improved in-service performance.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in