Fig. 1

Fig. 1

The training and education of engineers is hurt by the pandemic and the associated restrictions imposed everywhere We hear of the difficulties experienced by schools and colleges, and the heroic efforts of teachers and students alike in continuing their work on-line. But in engineering and many other practical disciplines on-line study is only part of the process. To emphasize this point, one can compare the training of medical doctors and nurses; they need practical training on the job. Would we be comfortable being treated by a doctor or nurse whose only training had been on the internet? Would we be comfortable with any product of engineering — an aeroplane, a dentist’s drill, a tunnel, a tractor — which had been assembled by technicians with no practical training?

It seems clear from this that the adjustments needed to combat the pandemic go far beyond the training that is possible to accomplish on-line.

Practical training involves hands-on experience of procedures such as assembly and disassembly, and the use of many kinds of tools from the simplest hand-tools to sophisticated machine tools and their controls. In recent years we have seen the publication of large numbers of videos which teach some of these practical skills: for example, how to build a bicycle wheel or how to re-wind an electric motor. Although the quality is variable, many of these videos are so good that they could inspire or even replace the professional instructors in colleges. In my own case I often wish I’d had such good facilities and teaching skills when I taught laboratory classes in the university. In most of these videos the instructor is teaching procedures for the student to execute at home. This is clearly a smart way to overcome the pandemic restrictions.

However, it must be said that the internet videos are not coordinated into a systematic training programme. Good as they may be, they are generally not designed to cover an entire syllabus with all the necessary background and foreground skills and theory. Rather, they appear in the guise of one good laboratory session, often limited to just one session of an hour or an afternoon. There is no examination, and no institution administering standards and issuing certificates by which students can qualify themselves to future employers. The “laboratory equipment”, tools and materials used by each individual student can hardly be standardized or confirmed to reach a level consistent with best industrial practice, and the more sophisticated factory processes and tooling will be inaccessible in even the best home workshop.

Therefore we should perhaps turn our attention to the role of industrial training schools. Sometimes lodged on works campuses in larger companies, or tucked away in one or two rooms in small companies, these training schools perform a vital function in the education of engineers and technicians, just as university hospitals do in the training of doctors and nurses. They can be found in almost all industrial communities. While their obvious role is to train staff for the particular business of the company, many of them run a wider curriculum of learning in order to provide a deep and thorough grounding in cognate subjects and theory. They often do this in collaboration with local training colleges which are part of the public education sector, where specialists in topics such as mathematics or welding or chemistry can provide the necessary instruction that is not available in the company training school.

Now industrial companies have to continue to operate and work within the pandemic restrictions, and if they were not doing this heroically we would all soon be hungry. So it seems natural to ask whether the role of training schools could be recognized as a vital activity in the public interest, especially if they can introduce measures such as “social distancing”, the wearing of masks, attention to hygiene, and personal protective equipment as appropriate in the different businesses. One would think it were a worthy candidate for the investment of public money in the form of grants to help the various training programmes to continue. It would help to focus attention on the importance of apprentice training.

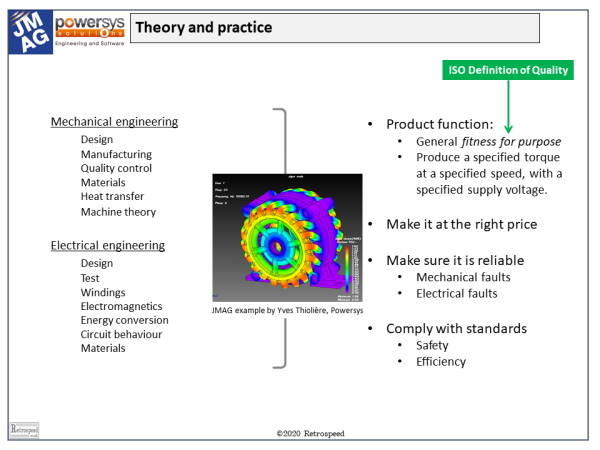

In the Figure I have set out two columns to try to distinguish the kinds of skills which are taught in college classes, and those which must be learned and practised in the factory. On the left is a list of topics, mainly theoretical, which might form the basis of a more detailed undergraduate syllabus in mechanical or electrical engineering. On the right is a list of requirements which apply to every manufactured product. This list implies the need for a wide range of practical skills, and even organizational skills, which go far beyond the limits of the theoretical foundations. In the middle I have planted an image from a very sophisticated numerical simulation, to suggest that such simulations are capable of contributing to the educational process for engineers progressing from the purely theoretical domain into the factory. The numerical simulation requires a tool which happens to be a software tool, and it must be the case that students can be trained to use this tool without knowing all the details of how it works — in exactly the same way that one can learn to use a welding torch without knowing all the details of how the welding equipment is designed and controlled.

This must be a challenging but stimulating time for all who carry responsibility for training and education, to consider the possible reorganization of the sites where the various practical exercises are undertaken. At a time when college laboratories may be closed or restricted, how much can be transferred to company training schools or laboratories, and how much can be done in home workshops? How much of the instruction and supervision can be done on-line? What is the role of simulation tools? And most importantly, can these issues be considered in a coordinated way by the public education authorities and the representatives of interested parties including industrial companies and the students themselves? Can we envision a system of training and education for engineers, in which all the available assets (software, tools, sites, and instructors) can be more integrated and work with coordinated systems of syllabus-planning and certification?