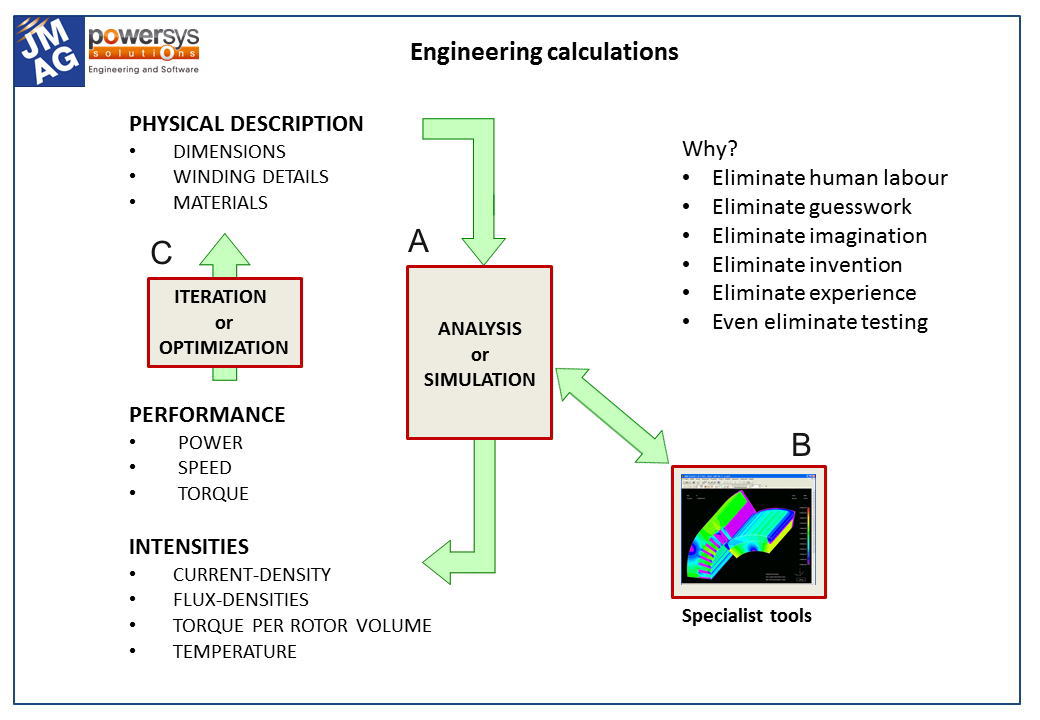

Most engineering calculations take the path of analysis or simulation, shown in Fig. 1, A. Analysis has been established for a long time; but simulation is more recent, especially with digital computers. The process usually begins with physical dimensions and material properties as input data, and the results usually include performance data (such as power, torque, efficiency), together with “intensity data” or “utilization data” (such as current-density, flux-density, power-to-weight ratio, etc.). Specialist tools B (such as the finite-element method) improve the accuracy and help with complicated cases.

In a complex project such as the design of an electric machine, process A includes the organization and coordination of the calculations. There is no standard software tool for this process. On the contrary, one can find a wide variety of methods used in different factories. Some of them are very old. They serve the important function of recording the technical details of the company’s products over many years or even decades. Others are completely new and open, especially in the development of new concepts. It is normal for the core analysis function A to contain a mixture of methods and software tools. The specialist tools B do not perform this coordinating function; instead, they serve it with essential reliable data on specialist aspects. They are usually focussed on a particular set of physics equations (such as Maxwell’s equations).

The ANALYSIS process A is essentially a one-way process, in which certain parameters take on the roles of input data, and others serve as output data. In practice we would often like to reverse the process: to start with the performance data and the intensity or utilization data, and end up with the physical dimensions. This implies synthesis rather than analysis. The synthesis process is performed by designers, who exercise imagination, invention, ingenuity. These attributes cannot be programmed in software, and that is why we need process C, “ITERATION OR OPTIMIZATION”. And we really do need it, because even the best designers cannot synthesize a design in one pass. Designers have always had to iterate, refine, and make incremental improvements. Process C is therefore an exciting area of development. It can help the designer get a better result. Also, to the extent that it can take on some of the coordinating and organizing functions of process A, it can become the key to the integration of the entire tool-set.

Fig. 1 Engineering calculations A,B,C

Fig. 1 Engineering calculations A,B,C