Overview

In the optimal design of electrical machines – where numerous and often conflicting requirements must be met – global design space exploration is essential. This requires evaluating a vast number of design candidates, making computational speed a major challenge. This is essentially true for applications such as induction heating coils, which involve 3D magnetic circuits and require coupled magnetic and thermal analysis. In such cases, achieving optimization within development lead time becomes a critical issue for practical implementation. As a solution, surrogate model-assisted optimization has garnered attention.

In this case study, we used JMAG to optimize the geometry of an induction heating coil with surrogate models. We evaluated both the validity of the analysis results and the degree of computation time reduction.

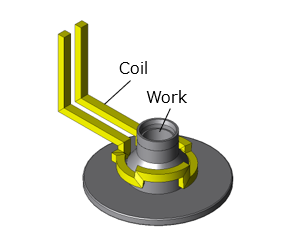

Fig.1 Initial Geometry of the Induction Heating Coil

This case study focuses on optimizing the induction heating coil geometry. Objective functions included minimizing temperature deviation, temperature bias, and Joule losses. Design variables were defined as the coil’s dimensions and positions.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in