Circuit / Control

- Sort condition

- Newest first

- Oldest first

- Large number of views

-

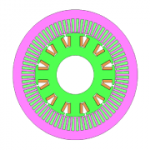

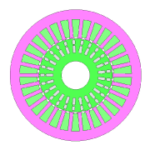

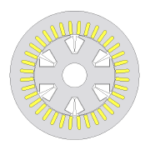

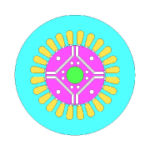

[RTML-062] WFSM_09 Open-End Winding

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 400(mm) | Height: 65(mm) | Voltage/Current: DC300(V)/283(A), DC600(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

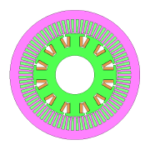

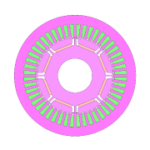

[RTML-061] PMSM/IPM Constant rating 100(kW) 3-phase, Open-End Winding

Type: PMSM | Max Power: 100(kW) | Stator(Outside Diameter): 250(mm) | Height: 259(mm) | Voltage/Current: DC350(V)/400(A) | Rotor: IPM

-

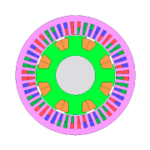

[RTML-060] IM Constant rating 100(kW)

Type: IM | Max Power: 100(kW) | Stator(Outside Diameter): 200(mm) | Height: 65(mm) | Voltage/Current: DC500(V)/600(A) | Rotor/Mover: Cage

-

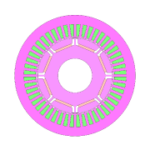

[RTML-059] IM Constant rating 100(kW)

Type: IM | Max Power: 100(kW) | Stator(Outside Diameter): 125(mm) | Height: 259(mm) | Voltage/Current: DC600(V)/400(A) | Rotor/Mover: Cage

-

[RTML-058] IM Constant rating 10(kW)

Type: IM | Max Power: 10(kW) | Stator(Outside Diameter): 92.5(mm) | Height: 37(mm) | Voltage/Current: DC440(V)/200(A) | Rotor/Mover: Cage

-

[RTML-057] IM Constant rating 1(kW)

Type: IM | Max Power: 1(kW) | Stator(Outside Diameter): 57.5(mm) | Height: 20(mm) | Voltage/Current: DC100(V)/28.3(A) | Rotor/Mover: Cage

-

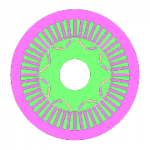

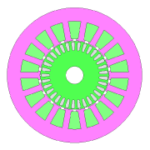

[RTML-056] WFSM_08

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 400(mm) | Height: 65(mm) | Voltage/Current: DC500(V)/283(A), DC600(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

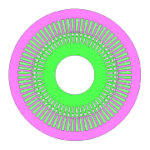

[RTML-055] WFSM_07

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A), DC600(V)/45(A) | Rotor/Mover: WF | Number of Phases: 3

-

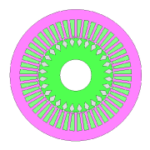

[RTML-054] WFSM_06

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A), DC200(V)/20(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-053] WFSM_05

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 185(mm) | Height: 50(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/35(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-052] WFSM_04

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 185(mm) | Height: 40(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-051] WFSM_03

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 115(mm) | Height: 150(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/15(A) | Rotor/Mover: WF | Number of Phases: 3

-

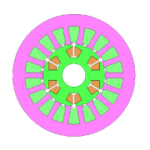

[RTML-050] PMSM/IPM 3-Phases Delta

Type: PMSM | Power: 150(W) | Stator(Outside Diameter): 112(mm) | Height: 65(mm) | Voltage/Current: DC24(V)/4(A) | Rotor/Mover: IPM

-

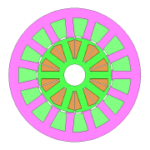

[RTML-049] PMSM/IPM Constant rating 75(kW) 3-phase Resolver

Type: PMSM | Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A) | Rotor/Mover: IPM

-

[RTML-048] WFSM_02

Type: WFSM | Max Power: 2(kW) | Stator(Outside Diameter): 260(mm) | Height: 60(mm) | Voltage/Current: DC200(V)/20(A),DC100(V)/10(A) | Rotor/Mover: WF | Number of Phases: 6

-

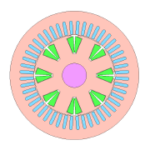

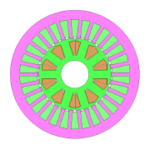

[RTML-047] PMSM/IPM Constant rating 75(kW) 3-phase

Type: PMSM | Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A) | Rotor/Mover: IPM