IPM Motor

- Sort condition

- Newest first

- Oldest first

- Large number of views

-

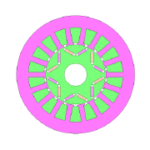

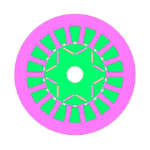

[RTML-013] PMSM/IPM Constant rating 10(kW) 3-phase

Type: PMSM | Max Power: 10(kW) | Stator(Outside Diameter): 115(mm) | Height: 106(mm) | Voltage/Current: DC240(V)/60(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 23(N·m)

-

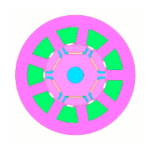

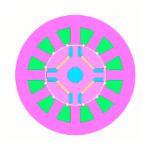

[RTML-011] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 25(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.7(N·m)

-

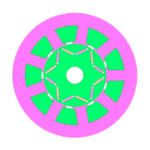

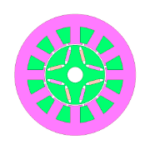

[RTML-010] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 27(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

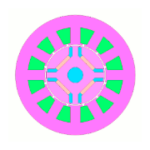

[RTML-008] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 22(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

[RTML-007] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 20(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

[RTML-005] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 80(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

[RTML-004] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 77(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

[RTML-002] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 54(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

[RTML-001] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 51(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

[L-MB-186] System Integration and Verification Using High Accuracy Plant Models

In this case study, the detection of current anomalies was verified by simulating an open winding fault.

-

[L-MA-185] Virtual Prototyping Enables Immediately to Validate the Machine Performance

In this case, invisible losses were confirmed at the operating point in the high-speed range (12,000 rpm), where phenomena are complicated by weak field magnetization and high fre…

-

[L-HT-184] Cooling Performance Evaluation for Motor Magnetic Design

Industrial motors, especially those with high power density, must take the cooling performance into account even for the magnetic performance with cooling. To improve the magnetic…

-

[L-VI-183] Evaluation of System-Level Vibration Caused by Motor Electromagnetic Forces and Torques

Motors are the power source that is incorporated into a system like eAxle, and the torque and electromagnetic force (excitation force) generated by the motor is transferred throug…

-

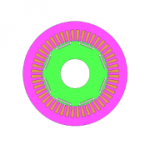

[JAC302] Optimization of IPM Motor Geometry and Coil Turns

This case study optimizes IPM motor geometry and coil turns by using objective functions to maximize the average efficiency of several operating points and minimize the volume to …

-

The Future of R&D and Design: What Can Electromagnetic Field Analysis and Artificial Intelligence Do for You?

Hajime Igarashi, Hokkaido University

-

Improvement of Motor Design Process through Topology Optimization and Parametric Multi-Objective Optimization

Hisayoshi Takeuchi, DAIHATSU MOTOR CO.,LTD.