Wound-Field Synchronous Motor

- Sort condition

- Newest first

- Oldest first

- Large number of views

-

[L-OP-187] Multi-disciplinary Evaluation for Optimal Design Without Rework

In this case study, we optimize a wound field synchronous motor (EESM) with two objective functions - average efficiency under the WLTC driving cycle and maximizing torque.

-

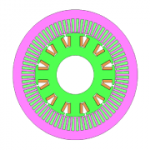

[RTML-062] WFSM_09 Open-End Winding

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 400(mm) | Height: 65(mm) | Voltage/Current: DC300(V)/283(A), DC600(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

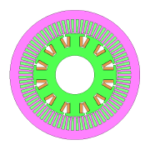

[RTML-056] WFSM_08

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 400(mm) | Height: 65(mm) | Voltage/Current: DC500(V)/283(A), DC600(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-055] WFSM_07

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A), DC600(V)/45(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-054] WFSM_06

Type: WFSM | Max Power: 75(kW) | Stator(Outside Diameter): 212(mm) | Height: 200(mm) | Voltage/Current: DC600(V)/250(A), DC200(V)/20(A) | Rotor/Mover: WF | Number of Phases: 3

-

[RTML-053] WFSM_05

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 185(mm) | Height: 50(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/35(A) | Rotor/Mover: WF | Number of Phases: 3

-

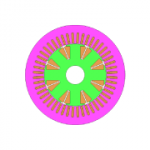

[RTML-052] WFSM_04

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 185(mm) | Height: 40(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/50(A) | Rotor/Mover: WF | Number of Phases: 3

-

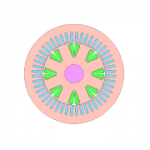

[RTML-051] WFSM_03

Type: WFSM | Max Power: 10(kW) | Stator(Outside Diameter): 115(mm) | Height: 150(mm) | Voltage/Current: DC240(V)/84.8(A), DC300(V)/15(A) | Rotor/Mover: WF | Number of Phases: 3

-

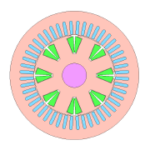

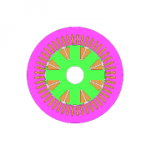

[RTML-048] WFSM_02

Type: WFSM | Max Power: 2(kW) | Stator(Outside Diameter): 260(mm) | Height: 60(mm) | Voltage/Current: DC200(V)/20(A),DC100(V)/10(A) | Rotor/Mover: WF | Number of Phases: 6

-

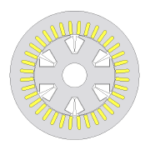

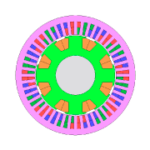

[RTML-044] WFSM_01

Type: WFSM | Max Power: 2(kW) | Stator(Outside Diameter): 260(mm) | Height: 60(mm) | Voltage/Current: DC200(V)/20(A),DC100(V)/10(A) | Rotor/Mover: WF | Number of Phases: 3

-

[JAC294] Design Exploration of Wound-Field Synchronous Motors, Including Evaluating Part Temperature and Stress

In this example, the efficiency map, part temperature, and stress, are evaluated at the same time for the motor design plan, and a design plan that meets the requirements is explo…

-

[JAC299] Inverter Changeover Control for an Open-end Winding Motor (Wound-Field Synchronous Motor)

This case study runs a circuit simulation of an open-end winding motor drive system that switches from using a single inverter to dual inverters during operation in order to mitig…

-

[JAC297] Geometry Optimization of a Wound-field Synchronous Motor Including Efficiency Map, Part Temperature, and Stress Evaluations

This case study runs a parametric optimization of a main automotive engine to maximize efficiency and torque while minimizing the temperature and stress as constraint conditions.

-

[L-MO-54] JMAG-Express Online

JMAG-Express Online is a Web service to support your motor design work anytime, anywhere.

-

[JAC289] Efficiency Map Creation for Wound-Field Synchronous Motors

In this example, efficiency maps for a wound-field synchronous motor are created to check the combinations of currents that result in maximum efficiency. In addition, the loss bre…

-

[JAC287] Analysis of Current Conditions for the Maximum Efficiency of a WFSM

In this example, we determine the motor efficiency in relation to the field current for a WFSM when the motor output is kept constant.