Takuya Yoshioka

CAE Eng. Dept. Product Design Key Technology R&D Div.,

DENSO CORPORATION

Abstract

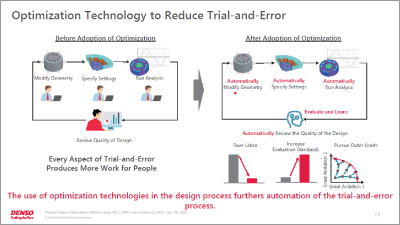

Product performance varies in characteristics due to various manufacturing error factors. To suppress design rework due to performance variation, it is important to optimize design considering variation from the upstream design stage. In general, evaluation of variation requires evaluation of a huge amount of error factor levels, and the computational cost becomes a bottleneck. In this presentation, we will report a case study in which HPC was used to speed up calculations and optimization calculations were performed for motors, considering variations.

To read Proceedings, please sign-in.

Protected content here, for members only.You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in