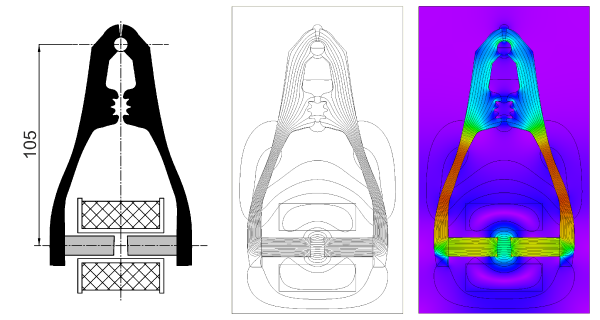

Fig. 1 Electromagnetic nutcracker

Powersys has just announced a seminar1 on the use of JMAG ‘to simulate, optimize, and co simulate the most critical small components: frameless motors, actuators, encoders, and beyond’.

What a good idea!

The announcement specifically mentions ‘robotics’ and ‘robotics engineers’ and it states that ‘agile, compact systems—from cobots to surgical bots—need electromechanical precision that goes far beyond traditional simulation tools’.

The field of electromagnetic actuators does indeed extend far beyond the conventional electric machine. We have only to think of relays, solenoids, torque motors, and even loudspeakers and signalling devices, to see the range not only of applications but also of concepts and configurations. While such devices may be less prominent and almost unknown to many engineers, their importance cannot be overstated. They are often found performing critical functions, just as the Powersys announcement suggests.

Although there is a very long history of this class of electromagnetic devices, merging with the history of early electric machines, it is easy to see and imagine their importance going forward. In automotive systems, renewable energy sources, aerospace, automation and other industries, advanced technology generates an evolving need for actuators of many diverse types. In many cases new materials and higher forms of electromagnetic engineering are applied to advance the art, together with mechanical design, thermal analysis, control, and co-simulation. Co-simulation may be especially important because of critical timing requirements in the action of the device and the system it serves.

When I first read the Powersys announcement I reached for my yellowed second-hand copy of Roters [1] and thumbed through it, to see what was the parlance in this business two or three generations ago. My eye fell on terms such as ‘Flat-faced armature type of magnet’; ‘Graphical evaluation of magnetic force’; ‘Final temperature rise’; ‘Tapered plunger type of magnet’; ‘Magnetic force in terms of inductance’; ‘Data for paper-section coils’; ‘Flux-current loop’; ‘Release time—Magnet with shunt condenser’; ‘AC magnet versus DC magnet’, ‘Sample design of a simple relay’; ‘Leakage coefficients’; ‘Materials for permanent magnets, iron, and iron alloys’; and many others. In five minutes browsing through this old classic from 1941, I felt I could see the scope of the complex and intricate art of actuator design. I’m sure that’s what Powersys will present, probably with many items not known to Roters.

Roters is one of the much-loved and often-quoted classical authorities in this field, but without disrespect we can say that his methods are by now antiquated—still valid, but antiquated—and they would not satisfy the modern engineer in terms of flexibility or accuracy. They might be valuable in preliminary design and general principles, and they might warm the hearts of old-timers like myself: but we would soon be frustrated by the lack of power and flexibility in calculation. This is especially so, in the case of devices which require a comprehensive multi-physics methodology in their design (with special emphasis on accuracy).

One of the striking features in Roters [1] is his detailed treatment of soft magnetic materials. He gives detailed magnetization curves for a great many materials used not only in actuators but also in machines and transformers. Many of these materials are precursors of those we use today. He deals with initial magnetization and the complete hysteresis loop; minor hysteresis loops; extrapolation to extreme levels of flux-density; hysteresis and eddy-current losses; and the energy exchanges that take place in actuator operation (including the effects of hysteresis and residual magnetism). Then he presents many detailed design examples including temperature-rise calculations and dynamic operation.

Certain aspects of Roters [1] would frustrate the modern engineer. For one thing, his coverage of permanent magnets is almost completely obsolete, since in 1941 there were no ‘high-coercivity’ magnets at all, and the ‘best’ material was Alnico II. In every design example he gives a forthright temperature-rise calculation without ever mentioning current-density, based largely on empirical methods albeit well organized and justified by precise testing. The insulating materials available at that time were nowhere near what we have today, so Roters’ data on the space-factor of windings and the thermal behaviour in general is not representative of what can be achieved now. Also, since he did not have the finite-element method (or indeed any numerical field analysis), his calculations of permeance, force, and inductance seem primitive by comparison with modern methods. Yet they are based on solid foundations in electromagnetic theory and they have been widely used by generations of electromagnetic engineers. We are in no position to be critical! His rigorous logic, design methodology, and thorough use of test data would still provide an excellent example of those attributes today.

With this background I thought it would be fun to set up a hypothetical actuator design as an example on which some of the ideas in actuator design could be tested. Fig. 1 shows the concept drawing — an electromagnetic nutcracker. Imagine a specification for humanoid robots intended to work as care-assistants in old-folks’ homes. The specification includes a requirement to be able to crack nuts. (This becomes more difficult with advancing years). It might be permissible for the robot to use an accessory, rather than to be permanently fitted with a nutcracker gadget; and that is the origin of the wild idea in Fig. 1.

A nutcracker is such a common kitchen utensil that one would rarely stop to think about the challenges faced by its designer. Coming up with an electromagnetic version brought this sharply into focus for me. Once I had a rough sketch (Fig. 1) with some back-of-envelope calculations, I realized what a ghastly failure it was going to be. Of course I had to make a model of it in JMAG, but I fear that is only telling me what I already knew: it’s a disaster, it will never fly, and it will certainly never ‘fly off the shelves’ in a kitchenware boutique. It’s painful to realise that it is going to be too heavy; it is going to need a power supply; it is going to be too expensive; and it will have to pass through all kinds of safety certifications which may prove to be impossible. All this engineering, all this analysis, . . . just to crack a nut? But as a school-book example of the challenges faced by engineers who design actuators, it may have some value (if only amusement).

There is an obvious but important underlying principle in this exercise: that is, the idea of suitability for purpose. I can apply all the ingenuity and all the analysis in the world, but if I’m starting with a crack-pot concept I’m going to fail. At least the analysis will tell me for certain why I’m going to fail. Then it will be unlikely that someone else will come up with an electromagnetic nutcracker and ‘eat my lunch’ (as the saying goes).

Notes

1 June 19

Register to Webinar: Electromagnetics Simulation for Robotics Innovation: Powering Precision in the Heart of Robotics (EU/IN Session)