Leading Motor Development for Mass Production Electric Vehicles

The SIM-Drive Corporation (headquarters: Shinkawasaki, Saiwai-ku, Kawasaki-Shi) establishes joint development projects for the mass production of electric vehicles (EV) using their vast experience and accomplishments in EV research. Hiroshi Shimizu, the pioneer of EV development in Japan as the Professor in Faculty of Environment and Information Studies at Keio University, heads the research and development as the Chairman of the SIM-Drive Corporation, a venture company. Osamu Shimizu from the In-Wheel Motor Propulsion Development Division related to the development of motors for electric vehicles discusses the current trends of EV development and how the SIM-Drive Corporation uses JMAG.

Unique Open Source Development System

Mr. Shimizu

Hiroshi Shimizu, a Keio University Professor and Chairman of the SIM-Drive Corporation, has made it our mission to provide the best technology and information for electric vehicles based on more than 30 years of knowledge and research for electric vehicles to related industries at the lowest possible price. We use an open source method to achieve this goal.

In other words, we establish joint development partnerships for a fee of 20 million yen for each development project we undertake for new electric vehicles. Our joint partners can be involved in all aspects of prototyping for the project and we provide the specifications, basic plans, and official copies of the testing results after the vehicle development is complete. Our joint partners are able to reduce their lead time and have access to the latest technology while we can devote ourselves to the technological development of electric vehicles.

34 companies and organizations invested and participated in our Advanced Development Project 1 that started in December 2010. Our first vehicle was completed in March 2011. Our second Advanced Development Project started in January 2011 with the support of 34 companies and organizations.

Mr. Shimizu

The name SIM-Drive comes from the first letter of each word in the phrase “Shimizu In Wheel Motor-Drive.” SIM-Drive includes all of the components and technology revolutionized for electric vehicles that have been developed by Professor Shimizu. More specifically, the SIM-Drive Corporation researches and develops drive systems composed of high performance in wheel motors, inverters, and batteries for component built-in frames. These technologies are not only limited to ground up models developed from scratched, but also focused on technology that can be applied to existing vehicles. The electric vehicles using components approved by SIM-Drive are identified as by SIM-Drive or platform by SIM-Drive.

The Advanced Development Project 1 that used this type of drive technology ran for 333 km on a single charge, which cleared our goal of cruising more than 300 km (JC08 mode = standard driving in a city for Japan). The capacity of the batteries that are used is almost the same as the capacity of the batteries used in EV on the market today, 24.9 kwh,. The AC electric power consumption of 77 Wh/km (watt hour/km) is equal to 1 litter of gasoline consumption, which corresponds to the energy consumed to run 70 km.

Advanced Development Project 1

Advanced Development Project 1

High Performance is Achieved from In Wheel Motors and a Hollow Structure

Mr. Shimizu

In wheel motors are motors that are installed in the wheel of vehicles that allow regeneration breaking when the motor accelerates or breaks by directly driving each wheel in addition to a dramatic reduction in the energy lost when power is transferred to the wheels from the motor. The energy that is used is reduced by 30 to 50 percent compared to on-board type vehicles that have the motor installed in an engine compartment, there is no transmission system for torque required, and there is more space allotted for the cockpit because of the simple structure that eliminates a motor in the engine compartment.

There are two types of motors; gear reduction motors and direct drive motors. The Advanced Development Project 1 utilizes an outer rotor type direct drive motor. These motors have a rotor with magnets arranged on the outside of a stator that coil is wound. There are small, mid, and large scale versions of these motors, but our research and development currently focuses on 65 kw large scale motors. One of the primary features of the SIM-Drive Corporation is developing vehicles that combine small, mid, and large scale motors based on the size, shape, and purpose of the vehicle.

The component built-in frame is technology where the main components, such as the batteries, are installed in the hollow area of the frame that has a robust hollow structure under the vehicle floor. An image of this technology would be a toolbox in the wheel area. The amount of space that can be used for the body of the vehicle is increased offering more freedom to the design and furthering the miniaturization of vehicles. This design also provides a safer driving experience because the center of gravity is lower. As I mentioned before, one of the main features of the SIM-Drive Corporation is applying technology to existing vehicles, which the component built-in frame allows us to do. For example, a used luxury vehicle could be converted into an electric vehicle.

Mr. Shimizu

The in wheel motor is really the heart of SIM-Drive’s technology. There are a wide range of aspects demanded of vehicles from the cruising distance to acceleration and low vibrations, which are all related to the innovation of motor technology for the EV. Analysis using JMAG is indispensable in the development and refinement of this technology.

For example, we built roughly 200 models as prototypes for the Development Project 1.Building the same number of actual prototypes would be require too much time and be too costly.

Being able to thoroughly examine the high performance during the development process is expanding around JMAG. Japan currently leads the world in the development of electric vehicles, but the competitive edge is gained by knowledgeable research and development teams that fully utilize tools like JMAG to provide the top motor technology to the rest of the world.

We also work in a system with our joint partners that invest in a development that centers around JMAG. For example, if our joint partner is a material manufacturer, they will provide data in a format that we can use in JMAG for material property data. Our EV development policy generally focuses on technology that uses common materials. Furthermore, the results obtained using JMAG provide invaluable evidence that gives us a strong negotiating position because we can show that a design is achieving the desired goals using these analysis results when moving forward to build the actual prototype.

Furthering Leading Edge Technology by Standardizing These Tools

Mr. Shimizu

JMAG was first implemented in 2004 in Professor Shimizu’s research laboratory at Keio University, not at the SIM-Drive Corporation. At the time, they had succeeded in developing an EV prototype and they implemented JMAG as a development and analysis tool for drive motors. They chose JMAG because it was easy to use. The user interface was clear and straightforward and they didn’t need to worry about entering mathematical functions. JMAG was also extremely powerful as a software, which is probably an obvious reason for choosing it.

JMAG is also been used by many companies and has become a standard in the industry as the electromagnetic field analysis software in the field of motors. The results can be utilized in a wide-range of other analyses because JMAG has become the standard in the industry. Japan provides the leading-edge motor technology in the world for electric vehicles because Japan is using analyses. The technology keeps advancing by combining design, analysis, and manufacturing using world-class fabrication of components.

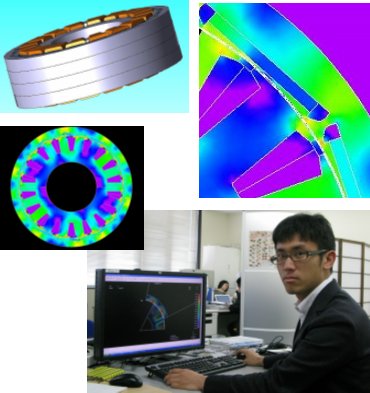

Motor analysis in JMAG

Motor analysis in JMAG

Mr. Shimizu

Users are a tough breed of people that will never be satisfied and they will always have complaints (Mr. Shimizu laughs). First, I would say that the terminology used for electromagnetic field analysis, which is obviously difficult, could be made simpler. The freshmen that are allowed to join the research laboratory at Keio Universities’ Shonan Fujizawa Campus become proficient with JMAG very quickly because it is so easy to use. However, they lack the understanding of the terminology surrounding the electromagnetic field analysis.

Mr. Shimizu

The Advanced Development Project aims to make the mass production of electric vehicles a reality by 2014. We believe that more highly efficient in wheel motors is the technology that will make this happen. I cannot go into detail about our current development, but we are focusing on a smaller motor that can rotate longer, or in other words, drive longer distances. The Advanced Development Projects generally last about one year and we need to complete our second prototype by next spring.

TECO Corp., a large electronics manufacture in Taiwan, is already planning a production line that aims to manufacture 100,000 units in 2013. The SIM-Drive Corporation is contributing to that development, but we hope that the mass production will be established as soon as possible to address the environmental problems of the world today.

Interviewee

In-Wheel Motor Propulsion Development Division

SIM-Drive Corporation

Shinkawasaki, Saiwai-ku Kawasaki-Shi, 212-0032 Japan

*The headquarters has moved

(Chairman of Benesse Holdings, Inc.)

Director: Hiroshi Shimizu

(professor in faculty of Environment and Information Studies, Keio University)

Research and development of in-wheel motors for electric vehicles

and other parts for electric vehicles

Consulting pertaining to the development of electric vehicles

Support for basic production of electric vehicles

[JMAG Newsletter Spring, 2011]