Louis Jäkel

Powertrain Engineering Department,

IAV Japan Co., Ltd.

Abstract

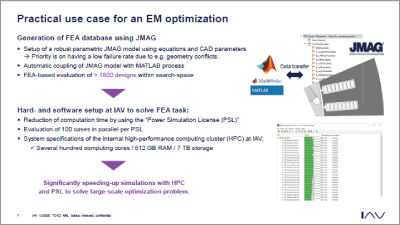

With artificial intelligence and machine learning, with big data and surrogate models, with high-performance computing and design-of-experiments: new developments have disrupted the field of e-machine design optimization recently. They promise to speed up the design, improve the results, widen the simulation focus and as such revolutionize the “old approach”.

On the other hand, well-founded concerns are discussed. How accurate could such a complicated system as an e-machine be predicted by simply memorizing what the algorithm has seen before? Don’t you require so many simulations to learn from, that the speed-up in optimization is over-compensated by generating the training data? Is it even possible to find optimal designs in parameter ranges that have not been thought of before? And how many mathematicians and IT specialists do you need to get this running?

This contribution gives an overview of the state-of-the-art approach in design optimization for traction drives. It provides practical experiences from over 5 years and dozens of projects using those technologies, highlights benefits and drawbacks. Additionally, it tries to answer those questions raised before – to alleviate existing concerns and to demonstrate, that these technologies are only a consistent evolution of approaches used and accepted for a long time. Are they hyped nowadays? Yes, clearly. But they will stay and improve our processes, even if they might not revolutionize what we are doing. Yet.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in