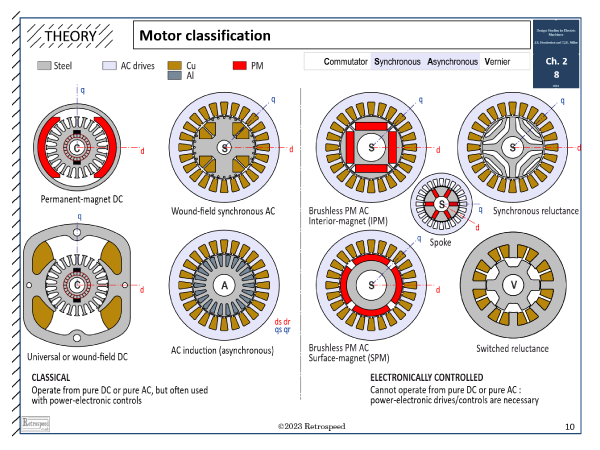

Fig. 1 Classification of electric machines by type or configuration

Fig. 1 Classification of electric machines by type or configuration

The folks who make some of our motors

Have problems producing the rotors :

Their magnet supply

Ran totally dry;

So now we must find a new modus.

Scarcity is nothing new in human history, and in electrical products we hear about it all the time in relation to lithium or rare earths, or even copper. So the poem might seem light-hearted, but actually it attempts to be serious. Let’s analyze it as though we were back at school.

“Folks” is a warm-hearted reference to our friends and colleagues in the manufacturing industry. Their problems are our problems; our solutions are their solutions.

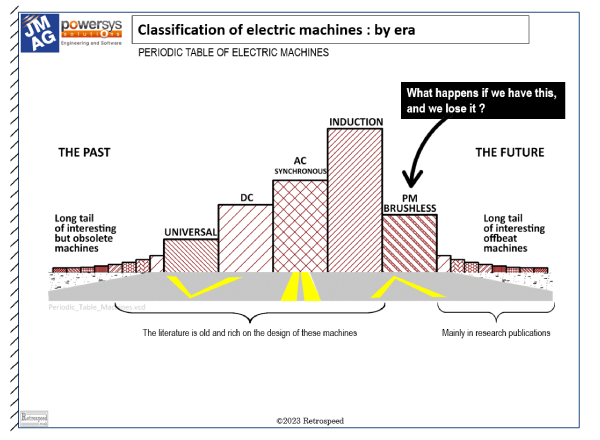

“Some of our motors” is not “All of our motors”. Have a look at Fig. 1 and Fig. 2. Only a subset of the family of electric machines uses rare-earth magnets. Of course it is an important subset, but it’s clear that there are alternatives.

Unfortunately the alternatives are not simple substitutes. The electric motor business is highly fragmented, in the sense that almost every electric machine is a specialty design that fits one application — and only one. It is true that some designs are mass-produced in large numbers, but that’s usually because they are fitted in a washing-machine or a motor-car that is itself produced in large numbers. Take that motor out of the washing-machine or the motor-car, and in all likelihood it will not immediately fit any other washing-machine or any other motor-car; it might be possible to re-purpose it, but not without serious modification to the motor itself and to the application — and all the factory tooling and supporting operations that go with every manufactured product. Change is disruptive, inconvenient, and costly. There is no electric motor that fits the description “one size fits all”. Nor is there a recipe for designing and applying electric motors that is simple and naïve — such as “just add water”.

That’s why we must find a new modus. Modus? The poet ran out of words that might rhyme with ‘motors’ or ‘rotors’, so he borrowed from Latin (supposedly obsolete like the DC motor!) And it works, because every engineer recognizes and practises the term Modus operandi (way of working) and every team member recognizes and practises the term Modus vivendi (way of living). Evidently, adaptation goes back at least to Roman times. And that is what the industry will do if it runs out of magnets.

To make this a little more technical, adaptations must surely be made not only in the motors themselves, but also in the applications. It seems that in the last 40 years the adaptations in both motors and applications have been jointly focussed on exploiting the fabulous properties of exotic magnet materials that far excel those of the magnets available to the ancients. If there is one parameter that characterizes the “Magnet Gold Rush” of the last half century, surely power density would be a good choice. Take the magnets away, and what must happen? Do we have to go back to the horse and cart?

Maybe in the long run, that is what we will have to do. But in the short term, we have two obvious paths. One is to feel our way into the wider family of electric motors, to find out the extent to which substitution of the rare-earth magnet motor is possible by other types of motor. This is very much the theme of the “Blue Book” [1], and it is planned to present a series of JMAG Videos in the form of a study that takes an IPM and develops nine different alternative motors in the same frame size. They do not all match the performance of the IPM, but the Blue Book and the related presentations describe a methodology for inventing, developing, and characterizing the various motor types using finite-element methods in the most efficient possible manner (so that the groundwork of concept formation can proceed on a sound basis).

Of the nine motors, six are permanent-magnet or reluctance motors (including spoke rotors and hybrid PM/synchronous reluctance motors of different configurations, some using ferrite magnets but none using rare-earth magnets), and the performance of all of these is disappointing. The remaining three — a wound-field (electrically excited) synchronous motor, a switched reluctance motor, and an induction motor — are considered to be more promising. But all the examples require extensive further work beyond the basic designs developed in the seminar and videos, and engineers who pursue that development will form their own opinions as to which is the best option. The specification in the study is a very loose, open specification; when the tight constraints and requirements of particular products are applied, the positions of these motors in the ‘league table’ may very well change.

Fig. 2 “Periodic table” of electric machines — classification by era

Fig. 2 “Periodic table” of electric machines — classification by era

The other path or modus is to look at the applications and adapt them. For example, with electric motor-cars we must ask the question whether we really need such high speed and acceleration and long range? The repair and reconstitution of cities suitable for human habitation surely can benefit from smaller, quieter, slower, gentler means of transport. Take away the rare-earth magnets, and we may need to accept a larger motor — a DC motor, a reluctance motor, an induction motor — with less power and less power-density, and that implies a lower payload and slower delivery. But that is the nature of adaptation, modus vivendi, modus operandi. Curious, isn’t it, that modus also means fashion. We don’t have to be addicted to the glitz of speed and acceleration; utility can be fashionable too, if promoted appropriately and served with the right engineered products.

Years ago, in the days before the ubiquity of the IPM, General Electric had a slogan for its employees, “Do more with less”. Whatever the motivation behind that slogan, the snappy words do seem to be relevant more widely, in any context of scarcity. Of course, as engineers we recognize that we will have a central role to play in any adaptation to any scenario involving scarcity of almost any commodity, and as analytical engineers we might have our own slogan, “Figure more, use less”.1 Not a bad modus operandi.

Further reading

J.R. Hendershot and T.J.E. Miller, Design Studies in Electric Machines, 2022 (the ‘Blue Book); sales@motordesignbooks.com

Note : Figure is used here to mean “calculate, simulate, use your computer!”