Explanation: Model-based Development

Recently, model-based design (development) is a term starting to be used in the development process. These reports discuss what model-based design is and how it is related to you in addition to how JMAG is utilized in model-based design. This report introduces the fundamental characteristics of model-based design.

Evolution of Model-based Design

The system development of automobiles is a primary example of when model-based design is often used in actual development. Units, such as the transmission, power steering, ABS, and drive control, are all controlled electrically by the software built-into the ECU making the electrical control of the engine a type of computer. These complicated ECU need to be examined to realize a system that moves as the driver desires while connecting these units. Of coarse, all of these units can be examined using a prototype vehicle, but the rework required when a defect is discovered could be immense. Front-loading development related to examining each units independently as well as at a system level is vital to reducing the cost and risk of development. This solution is referred to as model-based design. Model-based design is a method to evaluate a system (plant) by expressing each unit as a model and simulating the interface between each model virtually on a computer. Model-based design is advantageous to evaluate the entire system as the time lag of a single unit can have devastating effects to the entire system in the ECU used for communication. Model-based design may be a new term, but the actual concept has been around and is simply an extension of current processes.

In the past, information about parts was offered as diagrams and specifications. The system engineer would create the layout design based on these diagrams and manually calculate the performance and quality. In this case, the diagram equals the model. However, the information that used to be provided in diagrams is now offered as three-dimensional data following the standardization of 3D CAD. The concept of providing this information as a model has not changed even though the three-dimensional data now used as the model. Exchanging the information as a diagram may seem like a method used a generation ago now that using the three-dimensional data has become the expected format, but the idea is still the same. The geometry has evolved from two-dimensions on paper to three-dimensional digital data vastly increasing the amount of information, which in turn increases the expectations for higher performance. How will the machine operate if I apply voltage? The designs are now performed knowing how much performance can and cannot be achieved. Model-based design will also become a process everyone will learn, just as the geometry has evolved.

Solutions for Model-based Design in JMAG

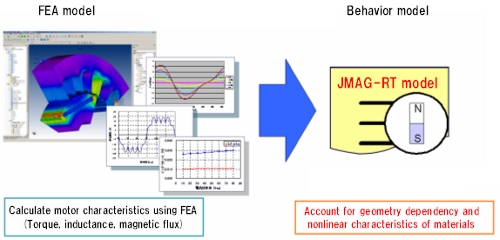

One of the solutions for model-based design provided by JMAG is JMAG-RT. The origin of the name steams from the goal of “support for JMAG in Real Time Simulations,” which is the ideal for model-based design. JMAG is capable of obtaining highly accurate magnetic field analysis results for electromechanical machines. Therefore, it has been conventionally used as a tool to further the designs created by the electromechanical engineers. However, electromechanical machines, such as motors and transformers, start to operate only after power is supplied by a drive circuit and the relationship between devices cannot be ignored. For this reason, the electromechanical design needs to be shared with the circuit and system designers. JMAG-RT was developed as a tool to transform the analysis results into a highly accurate model to provide a solution to share this information. For example, conflicting objectives including miniaturization, higher output, higher efficiency, higher quality, better control, and lower costs are required for motor development. This means that the nonlinear region of the magnetization characteristics have to be used resulting in the development of motors that are hard to handle from the inverter side. The key to development is knowing the final objective of the designs because the inverter itself is also under the same demands as the motor. Simulations using models that express the behavior like a prototype are required so that the final objective of both designs overlaps.

JMAG-RT is a tool that has already been used by many designers to convert the electromechanical machine into a model that can be utilized in the circuit/control simulator (behavior model). JMAG-RT is evolving to satisfy the needs of the market. Models of induction and SRM motors will be added to the PM, stepping, and linear motors that are currently available. A feature to incorporate iron loss in the PM motor model will also be added.

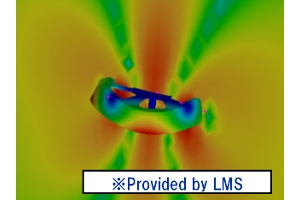

Noise analysis using LMS Virtual.Lab

Noise analysis using LMS Virtual.Lab

Induction heating analysis coupling JMAG-ABAQUS

Induction heating analysis coupling JMAG-ABAQUS

Model-based development is not limited to the control and electric circuit. JMAG is also continually improving performance through interfaces to third-party applications allowing vibration/noise evaluations using magnetic field and structural analysis models incorporating electromagnetic force and stress as well as temperature analysis using thermal and magnetic field analysis models incorporating current heat generation and heat to be performed easily. Thermal and structural behavior models will be developed in the future to meet the needs of the market.

This report has discussed the concept of model-based design and the efforts of JMAG toward model-based design. The next report will focus on the new feature of JMAG-RT to be released at the end of June.

[JMAG Newsletter Spring, 2011]