TODA RACING Co., LTD is focused on parts manufacturing, prototyping, and test stands mainly for racing.

We continue to undertake challenges with the motto of “Transforming Automotive Dreams into Reality” and satisfy customers with surprise and sentiment that exceed expectations.

Since its original establishment, TODA RACING Co., Ltd. has been involved in motorsports through many different projects including engine development and the in-house manufacturing of motorsports parts, with motors and inverters now also being manufactured in-house. TODA RACING Co., Ltd. is additionally engaged in a wide range of businesses that includes contract work such as prototyping and research-development vehicles, test businesses, and more. In this interview, we spoke to the chairman and founder Mr. Yukio Toda, as well as Mr. Kengo Toda, who recently assumed the position of president as of February, 2021.

Engaged in a wide range of vehicle-related businesses with a primary focus on motorsports.

Chairman:

We deal mainly in motorsports; development, manufacturing and sales related to vehicles such as racing engines, motors, inverters, and parts. We are also involved in contract work for prototyping and research-development vehicles as commissioned by OEM and parts manufacturers. Recent undertakings have been the development and manufacturing of test devices for manufacturers and universities. Next year, we plan on expanding our test buildings to accommodate various tests, as we’re seeing increases in the number of cases using test machines. Since we use a lot of electricity, this means that we’re currently in a situation where we don’t have enough test rooms. With expansions to test buildings, however, we anticipate being able to try many more things.

President:

We are indeed involved in contracts with sales agents in each country, focusing on motor sports racing parts.

50 years in manufacturing; Through technologies accumulated over this period, our strengths lie in research-development, manufacturing, analysis with actual machines, and testing, all made possible in-house. Simulations are used as a “virtual test bench”.

Chairman:

As we mentioned before regarding the nature of our company’s businesses, we’ve been involved in everything vehicle-related since our establishment right up until the present day. We are rather particular when it comes to how to proceed with manufacturing. From parts manufacturing and engine development, to present-day motor manufacturing, we now do everything in-house. Performing simulations, prototyping, and test machine development entirely in-house are our strengths. With tests, even in the event of differences with simulation calculations, we can quickly analyze whatever issue has gone wrong. We see exactly where the problem lies, whether that be a bad simulation method, or measurement method, or manufacturing method. We additionally cannot analyze these factors through measurements alone. These are confirmed with simulations, then further reflected onto the design.

We see JMAG as an instrument of measurement in a virtual environment, verifying from a different perspective prior to prototyping, then proposing for manufacturing how to reduce the need for prototyping as much as possible.

In the event that, at your company, the measurement results of a prototype machine are different to what was expected, there may be times where it is not possible to know what exactly caused those results from the actual machine measurements. We understand that the process is to return to simulations and clarify the phenomenon, then come up with countermeasures and reflect those onto the design, and create prototypes again.

Chairman:

Yes, the motor is important too, but also of particular importance is the engine. It is very important to develop and manufacture an engine that is clean, as well as resistant to disasters and excelling in durability. While trends at the moment are EV and electrification, engines have merits all of their own. We are also looking at various provisions to be made against disasters, and the development of clean engines such as with hydrogen.

In terms of motors, we also handle motors used for drones, and are even looking to flying car.

The factors in deciding to finally introduce JMAG were that it is produced here in Japan, and was recommended by reliable colleagues.

Chairman:

Well, we’d originally known about JMAG for quite some time. We first heard about it from a study group known as OVEC in Okayama. We originally started motor development just as a hobby some 10 years ago, but we weren’t using any tools in particular. It was 10 years ago that we also took part in the development of in-wheel motors at the Okayama Vehicle Engineering Center for the next EV (OVEC). That’s where we began considering business in motor development. If our company was to undertake motor design for other companies as a business, we thought that both testing and analysis would become necessary. As so to improve on accuracy, we then decided to introduce simulation software. We of course compared various different simulation software, but in discussion with the many experts around us, it was JMAG that was recommended if we ever wanted to make anything decent. It was JMAG’s high accuracy, and the fact that it’s developed here in Japan, that were the deciding factors in introducing it to our company.

That being said, we soon had some difficulties because we weren’t able to operate it intuitively. While we recognized that JMAG had a wealth of functions, such as setting points and results analysis, we did however feel that things were just a bit confusing. Training people takes time. Considering the hours of work involved, we’d like to see some sort of interface that’s slightly easier for beginners to understand. We imagine this to be something like a kind of navigation device.

The development of test machines is also carried out simultaneously, with actual measurements and simulations repeated. One effect of using simulations is that analysis results can be reflected onto the design.

Chairman:

We deal with a variety of different motor types. Not just IM or IPM, but also axial gap motors, among others. It’s not just their performance, but also their durability and how easy they are to manufacture that we need to investigate.

We are therefore simultaneously developing test machines and repeating actual measurements and simulations. If results don’t match, then we investigate that the problem might be due to something in the simulation, measurement, or manufacturing method. Factor analysis can’t be done just with measurements alone. It is only because of the introduction of simulations that we are able to reflect analysis results onto the design.

President:

We have 48 employees. 10 of those are in charge of analysis which includes analysis other than that of JMAG. Analysis targets are everything related to vehicles. This includes engines, motors, inverters, ECU, and transmissions, etc. Because we have one person dealing with various different things, this means that we always have someone in charge performing simulations.

Chairman:

We are, as an R&D initiative, currently investigating various different motor types in accordance with their application.

We have our own test patterns, and with the results of those tests we determine suitability for each application, and convert this into data.

In certain applications, axial gap motors also have a significantly high performance. We think that we’ll be seeing more of them around the world in the future.

President:

Analysis content is various. As a result, it’s not summarized as material in any procedural documents. Those in charge will check the analysis models and provide advice on settings and numerical values, etc. In addition, there’s many regional seminars that have been held before, and more recently, even online seminars. We participate in these and collect information related to analysis. We’re very grateful that even if long distances are involved, the increase of online content means that we can also use this for in-house education.

When designing traction motors, examining heat and cooling is essential. Of particular importance is modeling contact thermal resistance.

President:

Well, our company has plenty of experience in thermal evaluation for engines. This means that we’ve also accumulated experience in modeling methods for contact thermal resistance.

The example that we provided at the JMAG Users Conference was with our collaborative research with the Industrial Technology Center of Okayama Prefecture. Two slots are cut out from the stator core, and the contact thermal resistance is actually measured which is then reflected onto the model.

President:

Not for each motor, no. The contact thermal resistance is measured for each motor type, then stored in the database.

In the event of any minor changes to the same type of motor, we refer to this database and reuse it.

JMAG Users Conference 2020 Presentation Content

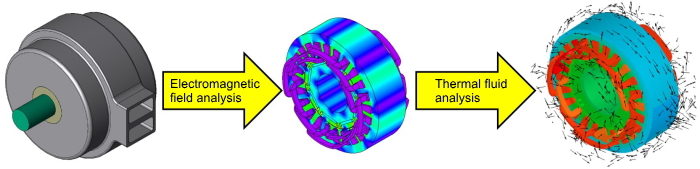

Figure: The thermal fluid analysis results of coupled analysis from electromagnetic field analysis results with a detailed model (temperature distribution)

Figure: The thermal fluid analysis results of coupled analysis from electromagnetic field analysis results with a detailed model (temperature distribution)

A future endeavor we’d like to challenge is optimization.

President:

We’re thinking that we’d like to use optimization even more in the future. In addition, with JMAG-Express Online, we’ve heard that we can run coupled analysis with Romax vibration analysis taking the lead. So we’d also like to start our front-loading initiatives for vibration analysis.

Chairman:

We do. A couple, in fact.

・We’d like to import and export CAD I/F using STEP, rather than SAT.

・When opening files with JMAG-Express, past projects (templates) don’t appear. We feel that it’s a little impractical needing to specify folders each and every time. If possible, we’d like to see this improved.

President:

The reality is linkage with overseas software, and that large amounts of tools are integrated with a number of overseas vendors. We hope that JMAG will also interface with those tools.

There are still many things we’d like to accomplish. There really is a pure enjoyment to be found in working on creating with talented people.

Chairman:

In recent years, regardless of manufacturing field, I feel that Japan has lagged behind the rest of the world. What we’d like is for JMAG to continue doing its very best as a domestic manufacturer.

You mentioned earlier, by the way, that when it comes to implementing optimization, it is absolutely necessary to have a calculator. We think that it would be a good idea to involve whole regions regarding this. For example, collaboration with the Industrial Technology Center of Okayama Prefecture which you’re associated with. With your company already working so well together with other companies, what are your thoughts on this?

Chairman:

We have a great deal of many things that we’d still like to try. We’re constantly thinking about all kinds of ideas. For inverters, for example, we engage in conversation with employees who specialize in inverters, and mix in the good ideas. The same is true for outside the company. By making connections with others capable of doing what we are not, we are inspired, gain trust in that connection, and therefore forge a win-win relationship. There is certainly a pure kind of enjoyment to be found in being able to work with talented people. We too are very grateful for the measurement and analysis technology of the Industrial Technology Center of Okayama Prefecture.

TODA RACING TEAM activity

Between August 27 and 29, 2021, The TODA RACING TEAM participated in the 5th tournament of the all-Japan Super Formula Lights Championship, positioning 1st three consecutive times in Round 13/14/9, resulting in a total victory. We very much look forward to all your other victories in the future.

Super Formula Lights

Interviewee

Yukio Toda

Kengo Toda

- Developments, manufacturing, and sales of racing parts

- Developments, manufacturing, and sales of racing engines

- Developments, manufacturing, and sales of automobile parts

- Research and development of engine combustion efficiency, reducing fuel consumption, and lowing emissions

- Manufacturing and sales of teststand

- Developments, manufacturing, and sales of automobile in-wheel motors and onboard motors

- Manufacturing of aircraft parts

- Manufacturing of industrial machineries

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in