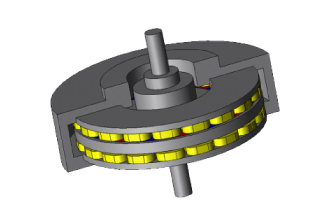

Axial Gap Type Motor

Axial-gap motors use an axial magnetic flux to rotate a disc-shaped rotor and stator facing each other. The advantage is that it can be constructed thinner than a radial-gap motor, and if properly designed, a high torque can be obtained relative to the magnetic flux density. The use of axial-gap motors expands to a wide variety of applications, including automobiles, and can meet market requirements with a design that takes advantage of its unique structure.

The JMAG Advantage

- Fast 3D electromagnetic simulation

- Mesh modeling that accurately captures short cogging torque periods

- Geometry modeling to capture AC losses in coils and eddy current losses in magnets

- Versatile material modeling function, such as evaluating core losses in soft magnetic composites

- Efficiency mapping function that accounts for these detailed losses

- Total evaluation can be made of the temperature rise due to loss and noise/vibration due to electromagnetic force

Case Study

JMAG Users Conference Presentations

Analytical/Experimental Verification of Thermal Characteristics of Axial Gap Motors, and Comparison Between Axial and Radial Gap Motors

Thermal characteristics of the flat-shape and high torque density axial motor are shown and the accuracy in thermal analysis (FEA & thermal equivalent circuit) modeling is studied by comparing experiment results.

Development of Axial-Gap motor for AGV

Introduces a study of torque ripple reduction of an 18-slot/20-pole double-sided axial-flux permanent-magnet synchronous motor and a comparison of efficiency maps of the actual machine and analysis.

Comparison of Axial Gap Motor with SMC Between Analysis and Experimental

Compares the output and efficiency maps of axial gap motor design and actual machines making use of soft magnetic composite characteristics in core geometry. The prediction of core loss due to DC superposition using a hysteresis model is also discussed.

Examination to Enhance Efficiency of Axial Gap Motors

The effects of the motor’s aspect ratio on N-T characteristics and efficiency, and how to reduce losses for high-torque, high-power motors were presented in axial gap motors using development case studies.

From Customer Specification to Prototyping: Three-dimensional Finite Element Simulation for Axial Flux Machines Constructed from Soft Magnetic Composite Materials

Total evaluation including machine, electromagnetic, and thermal is performed with FEA on a single-sided axial flux motor using soft magnetic composites effective for pumps and compressors in JMAG.

Sample Data

JMAG sample data for the examples used in the column contributed by Höganäs AB can also be downloaded from the Alvier Mechatronics website.

Soft Magnetic Composite Application Examples – Single Sided Axial Flux Machines –

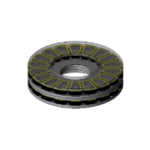

Soft Magnetic Composite Application Examples – Double-Sided Axial Flux Machines –

Application Catalog

please contact us.