JMAG-RT Models Connect Companies Changing Energy Management Development

The Sanden Corporation which designs, develops, and sells inverters for automobiles is planning motor based development using JMAG-RT models for control simulations by creating behavior models based on a proposal from one of their motor design manufacturers. Mr. Hirono and Mr. Tsukamoto, in charge of the design and development of inverters from the Electronic Development R&D Division, Mr. Sekine, in charge of evaluating motors from the Power Electronics Device Group, as well as a representative from the motor manufacture who proposed JMAG-RT to the Sanden Corporation, discuss the benefits of using JMAG-RT.

*JMAG-RT Model: A behavior model (motor model) generated from an FEA model that is used for control simulations.

Focusing on Enhancing Performance for Compressors in Hybrid Vehicles

Mr. Hirono

Our job focuses mainly on cooling and heating. The field of heating and cooling can be roughly broken into distribution systems for vending machines and refrigeration display cases for supermarkets and convenience stores, living and environment systems for EcoCute and wireless communication modems, as well as the field we are responsible for, automotive systems. We specialize in the design and development of compressors for air conditioners and HVAC units. Presently, we are particularly focused on enhancing the performance of electric compressors for environmentally friendly hybrid vehicles. Mr. Tsukamoto and I are in charge of the motor control design of electric compressors and Mr. Sekine manages the performance of motors.

Recently, the development speed to meet the requirements from our customers is increasing. We are now often required to deliver products within two or three months whereas, conventionally, we had a lead time of half a year. The time allowed for development continues to get shorter. Unfortunately, this means we have to constantly pressure the manufacturers that make the motors we purchase for speed in addition to miniaturization and cost reduction.

Representative of the Motor Manufacturer

My company develops motors as well as the peripheral devices of motors, such as gears and control devices. In the past, our customers required solutions to resolve energy conservation issues, or more specifically, problems related to efficiency. However, today, especially from automotive manufacturers, energy management is becoming a key word. Energy management refers to managing the energy of the entire drive system so that no energy is wasted. The design trends now require a design that not only simply aims for a peak torque, but also reduces the loss in the various drive regions. This means we can’t just focus on the region that will be used the most often, but rather, we have to improve efficiency and reduce losses with a balanced design.

Utilizing Electromagnetic Field Analysis

Mr. Hirono

The Sanden Corporation cannot simply tell the motor manufacture what we need. Therefore, we have an analysis specialist who investigates whether a motor fits the compressor characteristics that we desire. We implemented JMAG two years ago when Mr. Sekine commented that, “We can’t understand the high efficiency of a motor without understanding its magnetic field.” In that moment we realized that understanding motors, even as control designers, is indispensable.

Mr. Sekine

At first, we had no idea how to start using magnetic field analyses. However, we were able to start performing our own magnetic field analyses a month after implementing JMAG by participating in workshops and seminars. Now, we can easily refer to the contour plots and voltage waveforms we obtain from 2D analyses. We will analyze whether the motor that the motor manufacture has designed for us satisfies our requirements and we will request specific modifications to the motor manufacturers we use to reduce the number of prototypes that need to be built.

Mr. Hirono

We ask that the motor manufactures try to achieve the highest accuracy when performing simulations. If the values we have calculated differ from the actual motor control, not only do we have to re-measure the control side, we have to rebuild the control. There are obviously many different elements other than control, such as heat, vibrations, mechanical strength, and noise, but from a control designers perspective, we expect the motor model technology to be highly accurate.

Representative of the Motor Manufacturer

We design motors by providing our customers with a standard model while referring to products we have built in the past. Knowing the difference between the dimensions of prototypes and the designs is important to increase the design accuracy. For example, cases where the actual air gap is 0.58 when the air gap that is designed is 0.6. Understanding the correction factor of the actual motor and simulation is vital.

Mr. Hirono

In the past we have had to have the motor rebuilt when the required characteristics are not satisfied, but today, the characteristics that we have requested are usually fulfilled the first time we receive the motor.

Representative of the Motor Manufacturer

It has been 4 years since we implemented JMAG, but we have been using CAE for 10 years. We decided to implement JMAG because our simulations did not provide the results we needed when matching the simulated and experimented results, including the control. We recently started using JMAG-RT. Examining the motors independently is pointless for an analysis. We cannot provide the appropriate motor quickly without predicting how our customers will be using the motor and we work with them in the development and analysis. Using JMAG-RT between my company and the Sanden Corporation is being considered now to reduce the time required for developing motors. We only have to create one or two prototypes because the motor is shaped using simulations allowing us to meet the Sanden Corporations requirements quickly while also reducing the materials and labor that are required.

Hybrid Compressor

Hybrid Compressor

Enhanced HFC134a compressor

Enhanced HFC134a compressor

Natural refrigerant compressor

Natural refrigerant compressor

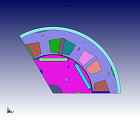

Model

Model

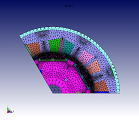

Mesh model

Mesh model

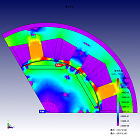

Magnetic flux density distribution (no-load)

Magnetic flux density distribution (no-load)

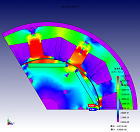

Magnetic flux density distribution (overloaded)

Magnetic flux density distribution (overloaded)

Benefits of Using JMAG-RT Between Corporations

Mr. Hirono

We originally used the ideal motor model in the control simulation tools, but we discovered the analysis results did not match the experimented results. One of our customers told us we could generate a motor model, JMAG-RT model, in JMAG to use with a control simulation. We then requested a JMAG-RT model be created for us to examine when the representative from the motor manufacture proposed that we use a JMAG-RT model. We are still considering the possibilities for JMAG-RT, but we know we would like to use JMAG-RT to analyze motors for the electric compressors of vehicles.

Representative of the Motor Manufacturer

I think the greatest benefit is being able to define the motor specifications while sharing that information with the customers. We are building motors based on the specifications required by our customers. Therefore, understanding whether or not we have “fulfilled the customer’s requirements” and whether or not “the specifications that are requested by our customers can be achieved physically” are very important. If the customer has specific specifications or needs, we can use JMAG-RT as a tool to communicate with our customers. Defining the specifications while sharing the analysis results and information is vital. The greatest benefit of JMAG-RT is probably the ability to define specifications and increase the speed of development.

Representative of the Motor Manufacturer

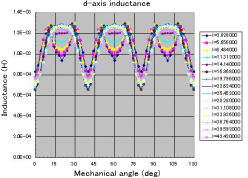

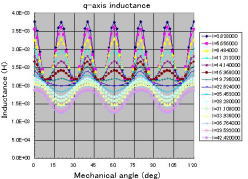

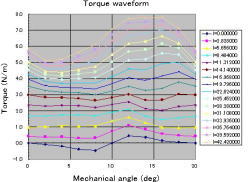

We compare the back EMF and torque constant of the motor and previous motors we have made as examples when creating a JMAG-RT model. After we confirm that the results are accurate, we provide the information to our customers. This time we confirmed the LdLq, back EMF, and torque constant before providing the JMAG-RT model to Mr. Hirono.

Mr. Hirono

The size of the data for the RT model is small enough that it is sent to me by e-mail.

d-axis inductance

d-axis inductance

q-axis inductance

q-axis inductance

Torque waveform

Torque waveform

Expectation for Model Based Development

Representative from the Motor Manufacturer

Currently it is a trial and error process where customers provide feedback, such as “these results were good, but we would like a little more here.” If our customers can test the exact specifications by operating the motor in the product that is being developed, such as the Sanden Corporation and other customers who are using JMAG-RT, they can be more specific about their needs. For instance, “there is no problem with the motor in the steady state, but there is a problem when overloaded or light loaded.” This increases the speed of development because we quickly receive the exact specifications and feedback from our customers. Because JMAG-RT has these various benefits, it is a convenient tool to support the needs of our customers quickly. Moreover, we can confirm whether or not there is any irregular movement in addition to whether or not the back EMF is accurate for the motor because the JMAG-RT behavior model is so accurate. I would like to use JMAG-RT to determine whether a motor is right based on the specifications we receive from our customers the first time around.

Mr. Hirono

For the Sanden Corporation, we plan on using JMAG-RT to confirm the parameters of a motor first. We currently receive the LdLq data from the representative of the motor manufacturer, but it is difficult to apply the information and explanation we receive because the results vary with the materials and current that are used. Therefore, first we would like to evaluate the parameters of the motor. In the future, we would like to evaluate the motor parameters, and then perform a coupled analysis of the compressor, motor, inverter, and inverter control. However, the challenge is determining how much of an analysis can be utilized under time and cost constraints. In the past, the control designer needed to understand the motor characteristics to some degree to use the motor effectively in the design, but JMAG-RT allows the control designer to use a motor in simulations without understanding the motor characteristics. I have also come to realize that JMAG-RT also accurately simulates the effects of high harmonics. We can continue the development of the control by determining that a motor is not right even without a prototype. We can cut costs by reducing the number of prototypes as well as, of course, reducing the time and labor required to examine those prototypes. These benefits are huge for us.

Electric compressor

Electric compressor

Interviewee

Electronic Development Group2

Electronic Development Group2

R&D Division

Sanden Corporation

Mr.Daisuke Hirono

Power Electronics Device Group

Power Electronics Device Group

R&D Division

Sanden Corporation

Mr.Kazutaka Sekine

Electronic Development Group2

Electronic Development Group2

R&D Division

Sanden Corporation

Mr.Takeo Tsukamoto

[JMAG Newsletter Winter, 2010]