Building on tradition, the Togami Electric Mfg. Co., Ltd., a manufacturer of power distribution and control equipment, makes use of their creativity and ingenuity to evolve with society and meet the various needs of the times.

Togami Electric Mfg. Co., Ltd. is a diversified manufacturer of power distribution and control equipment and handles products that are essential to social infrastructure. They respond to client needs and various contemporary needs with ingenuity and have expanded their business not only in Japan but also overseas. The interviewee, Mr. Nishimura is mainly involved in the development of medium voltage equipment for overseas markets.

They are committed to protecting people’s lifestyles based on the slogan, “Make the society, the earth and the future affluent”.

Mr. Nishimura:

The company develops and manufactures power distribution and control equipment, based on their corporate philosophy; “Make the society, the earth and the future affluent”.

I am with the International Division. Our department works across a wide area ranging from Southeast Asia to the United States. Our main work and my responsibilities are design and development of parts used in medium voltage equipment for the U.S. market.

Mr. Nishimura:

Since we are working with products essential to social infrastructure, we always make sure from the development stage that we are able to provide high quality products at low cost that meet performance requirements and don’t undermine customer confidence. There is just the right amount of tension in the workplace and I believe we have a good environment to work on development where it is easy to communicate with our superiors.

Mr. Nishimura:

In Japan, 6.6. kV is mainly considered medium voltage. (Voltage of general medium voltage equipment)

You may think that experimenting with medium voltage is difficult because of the dangers involved, but our company has experiment facilities equipped with handling all domestic products. On the other hand, the maximum for the products for overseas markets that I work with is 27 – 38 kV. Some experiments cannot be run for voltage at the 27 – 38 kV level.

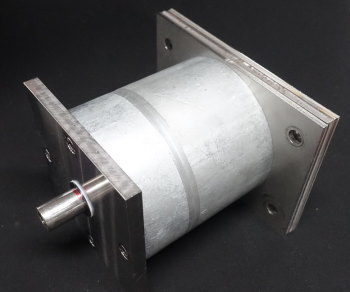

Figure: Prototype of Electromagnetic solenoid

Figure: Prototype of Electromagnetic solenoid

Checking correlation by repeating verification between analysis and the actual machine. Realizing the practicality of analysis by using it.

Mr. Nishimura:

The objective was in part to improve work efficiency by using the analysis results to reduce the number of prototypes created. In other words, reduction in development costs.

At the beginning, we were looking for an electromagnetic field analysis product for lease. It seems that a trading company introduced us to JMAG and that’s how it all started. Once we started using JMAG, we were handling more jobs and were using JMAG more frequently, so we decided to fully implement the software. We feel JMAG is a practical application, particularly for checking correlation with the actual machine as well as for other uses.

When I joined the company, JMAG was not used directly in product development, but I was placed in charge of using JMAG at the R&D Department where I worked.

At first, JMAG was used to check basic performance before creating a prototype at the beginning of the design phase. We used JMAG to identify the correction points from analysis results and re-validate. At the next phase, after seeing that performance requirements have been met, a prototype was created and the analysis results were compared to the performance verification results of the prototype. We use JMAG to run analysis over and over again to find better results and apply them to prototypes. As long as we are creating products, cost becomes just as important as performance, so we also use JMAG to find areas in the design that can be improved.

Mr. Nishimura:

At first, I was the only one using JMAG, so I called a few people working on development and conducted a review on how I used it. Then, other people started to use JMAG. This kind of review is conducted quite often at our company. There are many opportunities for such reviews, particularly in software that can be used for design like JMAG. The reviews are conducted to encourage people to actively make use of such tools.

Currently, I have a lot more projects to work on, and the colleagues who have succeeded my work are the ones primarily using JMAG now. I help out by answering questions when they come across something they don’t understand.

“Practice makes perfect”. Building up skills in the workplace by accumulating individual analysis know-how.

Mr. Nishimura:

Once a certain level of results is obtained, the analysis results and how these results are reflected in design are compiled in a report. The next user uses this as a reference. The environment for sharing and managing information has not been organized yet. Although the information on the model created is compiled in a report, only the person who created it knows the detailed settings and know-how for using JMAG. This information is not stored anywhere for sharing.

Likewise, for analysis know-how, rather than taking the time to provide guidance, we answer questions as they arise. Sometimes we give advice on better ways to do things while we watch how things go.

Sharing know-how is difficult. I personally think it is better to gain an understanding on the basics as you try it out on your own because modeling methods differ depending on what is being analyzed. Like the saying goes “Practice makes perfect”, I often give advice to my colleagues after they have achieved a certain level of competence.

Mr. Nishimura:

In general, people tend to have the impression that analysis software is difficult to handle, understand and use. Therefore, it took time to get used to it and it took almost 6 months for me to be able to run an elementary electromagnetic field analysis. It took a little longer after that to learn how to run a transient analysis.

Mr. Nishimura:

At first, I downloaded the analysis case sample (JMAG application note), a set of PDF and data, provided on the JMAG Website. I checked the settings and functions used in the sample and gained understanding as I went along. I also participated in seminars and gathered information for reference.

Even now, we try to get anyone starting JMAG to participate in the seminars. The content may not be directly related to our work because our company does not handle motors, but I check out seminars for content that may relate to our work and look into taking part in them.

Gaining deeper knowledge and understanding by visualizing unseen phenomena

Mr. Nishimura:

We mainly analyze solenoids. Our analysis results are mostly applied to products that make use of the thrust force output by a solenoid, such as switches.

I just mentioned that “we apply our analysis results to prototypes” but achieving an estimate that is 100% accurate is tough. We aim for about 80 to 90% accuracy because various external factors and mechanical structure loss have an effect on analysis. There is always a gap between the actual machine and analysis, so as long as it is not a fundamental issue, we use the simplified model for evaluation.

We place emphasis on evaluating items ranging from basic solenoid properties such as “magnetic circuits, magnetic flux density, demagnetization characteristics during motion in extreme environment, etc.” to items related to performance and quality of product motion conditions. The magnetic circuit depends largely on the plunger retention and solenoid motion. Our objective is to remove excess that will lead to losses as much as possible and exert the power required with the minimum of material and a simple structure.

At first, we were running static analysis. Now mainly run transient analysis. We run analysis by reproducing a state that is close to actual operations. We have expanded the range of use, including running demagnetization analysis. In other jobs, we even evaluate electric fields.

Mr. Nishimura:

As to what we run electric field analysis for, imagine something like a condenser. When there is a gap or damaged part in the resin, if a medium voltage is applied to both edges of the gap, a concentrated electric field is created in that gap. This concentration of electric field causes an electric discharge and eventually an electrical breakdown may occur in the medium voltage and low voltage parts. Therefore, we are trying to check whether a high electric field occurs locally by running an analysis.

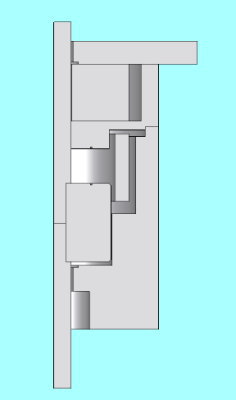

Fig.1 Cross section of simplified model

Fig.1 Cross section of simplified model

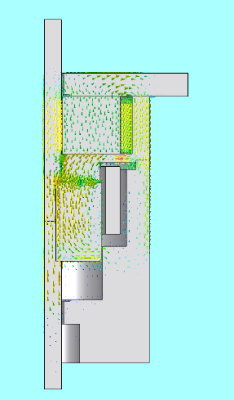

Fig.2 Image of magnetic flux during analysis

Fig.2 Image of magnetic flux during analysis

Fig.: Simplified model of product and analysis

Product Name: Electromagnetic Solenoid

Description: A general linear solenoid with a latch mechanism that uses magnets. Retention and motion speed of drive parts etc. are important design factors that determine the performance of the final product. This is because a considerable amount of electromagnetic repulsion occurs when introducing medium voltage devices and currents are applied.

Mr. Nishimura:

Yes, of course. Before we started using JMAG, we relied a lot on knowledge and intuition but that method results in many trials and errors. Prototypes need to be created but we have been able to significantly reduce the number of prototypes we create by making use of analysis software for parts where analysis can be applied. Until now, we were making a prototype for every change we made, but if we use analysis software, we can eliminate some of the phases in creating the overall prototype.

I also think that analysis helps to speed up the design work for engineers with less knowledge. Magnetism and electricity can’t be seen and that makes it difficult to design. It takes time at first when you’re not used to it. I am under the impression that being able to see it makes the designing much faster. Nonetheless, it is difficult to show in concrete numbers how much faster it has become.

The advantage of using analysis software is being able to easily try out design ideas through trial and error

Mr. Nishimura:

Yes, the advantage of using analysis software is being able to take a theoretical approach to using trial and error for design ideas. It is easy to try ideas such as “making changes in hopes that performance will improve” in analysis and verify it. It is also a great advantage to be able to deepen your own knowledge and understanding by repeatedly performing verifications. You are not the only one that is able to gain a deeper understanding. The advantage of using analysis software, to visualize unseen phenomena, also enhances the understanding of everyone else involved. Showing contour and vector plots makes it easier to explain the design intent in a review and makes it easier for people with less knowledge to understand.

Mr. Nishimura:

One issue is about how to view the correlation between the actual phenomena and analysis and how to apply the analysis results because magnetism and electric fields are phenomena that you can’t see. If something that is not accounted for in analysis is affecting the results, we may review the condition settings of the analysis or even review the overall method of running the tests. Right now, after correlating the results, we look for areas that can be improved based on individual knowledge and reflect it in the design.

The other is achieve further work efficiency. We have been gradually reducing design time but we still rely on the knowledge of the engineer creating the design to change geometry from analysis results and we are looking into whether we can streamline this process. In order to do this, we want to make use of JMAG’s optimization function but we have not been able to get around to it. Ideas derived from JMAG’s optimization function are likely to be better than ideas from an experienced engineer. We definitely want to use this function in the future.

Mr. Nishimura:

We accounted for eddy current from the initial phase and I think we are making sufficient evaluation now. So, we don’t intend to spend more time on this. Of course, after finishing verification in the actual machine, we will proceed to do so.

Mr. Nishimura:

I know that many JMAG users handle motors, but if JMAG would provide analysis cases for a wide range of applications, including solenoids, in the future, I believe users will be able to expand their use of JMAG to a wider range.

I think the user interface is easy to use and am totally satisfied as it is now. However, the model imported from external 3D CAD software looks slightly different from the way it looked in the original 3D CAD software and it would be extremely helpful if this could be improved.

Thank you for your cooperation.

Interviewee

Engineering Group, International Division

Togami Electric Mfg. Co., Ltd.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in