Koji Kokue

Engineering Affairs Sec. Engineering & Quality Management Dep., Tamagawa-seiki Co.,Ltd.

Abstract

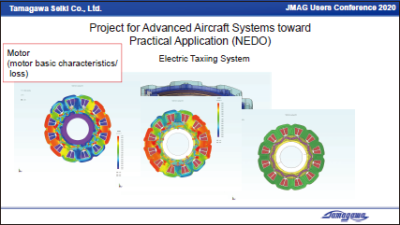

Machine tools have realized more complicated shape machining by equipping multi-axes such as 5-axis or combined processing machines which provide greater flexibility. Along with this, more accurate and more precise machining is rapidly required in recent years. In order to realize higher accurate and higher precise machining, it is essential to improve the accuracy of the angular sensors used in machine tools.

In response to the market demands, Tamagawa Seiki has been developing gear-type high-precision magnetic encoders. This development project was adopted for the Business Support Industry in FY2016 by the Ministry of Economy, Trade and Industry. As a result, our development has brought the high-accuracy of +/-10 seconds or less, in spite of having small-sized gears, by the introduction of self-calibration technology. In this research and development, we found that countermeasures should be taken against the magnetic interference phenomenon between AB phases and Z phase, which was an undetectable error until the high-precision angle detection is realized.

Here, I introduce an example which evaluated such magnetic interference phenomenon using the 3D finite element method.

You need to sign in as a Regular JMAG Software User (paid user) or JMAG WEB MEMBER (free membership).

By registering as a JMAG WEB MEMBER, you can browse technical materials and other member-only contents for free.

If you are not registered, click the “Create an Account” button.

Create an Account Sign in