Providing highly a reliable analysis requires faithfully implementing realistic physical mechanisms into simulation models as best as possible. We continue to develop modeling technology for JMAG to provide the best models at each stage, from micro behavior inside materials, to multi-physics phenomenon and control systems.

Material Database

JSOL has developed partnerships with material manufacturers to obtain the best possible data for JMAG’ s material database. Along with including stress dep e ndent magne tic prop er ties and iron l oss properties of electromagnetic steel sheets, we also continue work with our partners to provide data needed in advanced analyses.

Material Modeling

JMAG leads the field in material modeling technology.

Fast, detailed modeling methods are developed based on our understanding of characteristics for magnetic steel sheets, magnets, and powdered metals. Many companies use JMAG to help develop new materials, which ensures JMAG is always capable of capturing precise material responses.

Function

- Magnetization

- Temperature dependent material in thermal properties

- Accounting for the Temperature Dependency of B-H Curves

- Detailed Iron Loss Calculation for Degradation

- Modelling Accounting For Stress

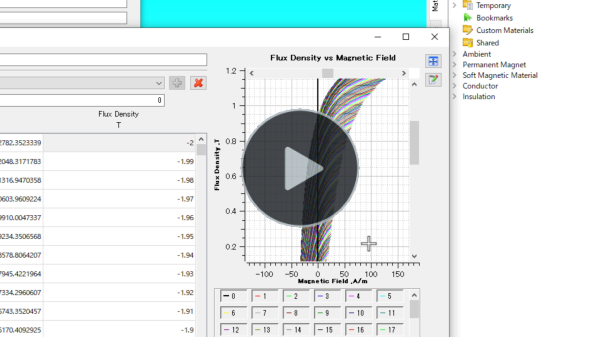

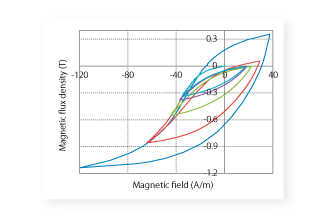

Creation of Hysteresis Curves Interpolated at Arbitrary Intervals

Improved the resolution of minor loops that can be taken into account in the play model.

Since the measured hysteresis curve can be interpolated and used for calculation, minor loops with smaller amplitude can be captured in magnetic field analysis.

Documents

Angular dependent Magnetization Characteristics

Improved analysis accuracy of magnetic anisotropy.

By using a material whose magnetization characteristics are input for each angle from the direction of easy magnetization, analysis that takes into account the magnetic anisotropy of the magnetic steel sheet can be performed.