LS

Iron Loss Calculation

- Sort condition

- Newest first

- Oldest first

- Large number of views

-

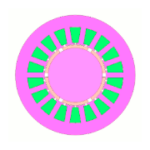

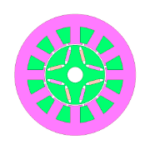

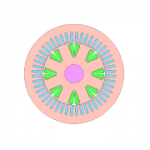

[RTML-009] PMSM/SPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 14(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: SPM | Average torque: 3.6(N·m)

-

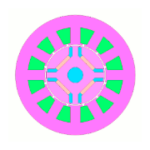

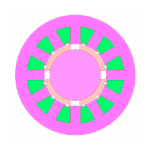

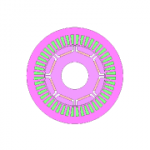

[RTML-008] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 22(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

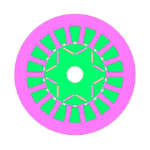

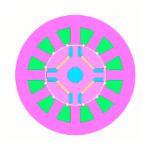

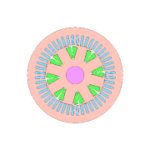

[RTML-007] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 115(mm) | Height: 20(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

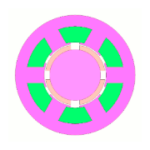

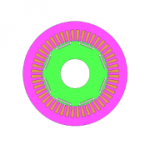

[RTML-006] PMSM/SPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 53(mm) | Height: 46(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: SPM | Average torque: 3.6(N·m)

-

[RTML-005] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 80(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

[RTML-004] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 77(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

[RTML-003] PMSM/SPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 53(mm) | Height: 36(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: SPM | Average torque: 3.6(N·m)

-

[RTML-002] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 54(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(flat) | Average torque: 3.6(N·m)

-

[RTML-001] PMSM/IPM Constant rating 1(kW) 3-phase

Type: PMSM | Max Power: 1(kW) | Stator(Outside Diameter): 54(mm) | Height: 51(mm) | Voltage/Current: DC100(V)/20(A) | Rotor/Mover: IPM(Vshaped) | Average torque: 3.6(N·m)

-

[JFT094] Parametric Analysis of Material Properties

In this document, a parametric analysis is run varying coefficients for an iron loss equation from case to case, and a procedure for obtaining Joule loss and hysteresis loss is pr…

-

[JAC302] Optimization of IPM Motor Geometry and Coil Turns

This case study optimizes IPM motor geometry and coil turns by using objective functions to maximize the average efficiency of several operating points and minimize the volume to …

-

[JAC293] Axial Gap Motor Geometry Optimization Using Surrogate Models

In this example, the dimensions of an axial gap motor are optimized by using surrogate models, then the Pareto curves and the effect of reduction in calculation times when using s…

-

[JAC298] Analysis of an SPM Motor Taking into Account the Effects of Layer Shorts

OverviewDeterioration in the coil insulation may cause a short circuit between adjacent coil layers (layer short). A short-circuit current flowing when the winding has a layer sho…

-

[JAC299] Inverter Changeover Control for an Open-end Winding Motor (Wound-Field Synchronous Motor)

This case study runs a circuit simulation of an open-end winding motor drive system that switches from using a single inverter to dual inverters during operation in order to mitig…

-

[JAC295] Inverter Changeover Control for an Open-end Winding Motor

This case study runs a circuit simulation of an open-end winding motor drive system that switches from using a single inverter to dual inverters during operation in order to mitig…

-

[JAC289] Efficiency Map Creation for Wound-Field Synchronous Motors

In this example, efficiency maps for a wound-field synchronous motor are created to check the combinations of currents that result in maximum efficiency. In addition, the loss bre…