Martin Bruell

Technology & Innovation,

Schaeffler AG

概要

Currently, there are two trends in machine development for electric vehicles. The first is to target high power densities using axial flux machines (AFM), which have become increasingly popular in traction drive systems, especially in the yokeless permanent magnet version (PM-AFM). The second is the reduction of rare earth materials due to supply chain risks and environmental concerns. With upcoming sustainability requirements, external excitation with a wound rotor (EE-RFM) is increasingly used in drivetrain applications. This offers the advantage of rotor speed independent excitation, making it ideal for variable speed drives, as in electric vehicle drivetrains. As a combination, the externally excited axial flux machine (EE-AFM) is introduced in this study.

However, due to added masses mainly from the rotor windings, the rotor stresses and the displacement are a major issue for EE-RFMs and require special attention while designing the machine. For an EE-AFM, the rotating masses do not interact identically, as the centrifugal forces result in additional bending of the carrier while causing stresses that affect both the electromagnetic performance and the structural integrity of the machine.

From electromagnetic perspective, optimizing an EE-AFM is challenging due to the interdependence of numerous parameters. Performance targets such as torque and efficiency are directly influenced by the design of the magnetic circuit and windings. In an EESM, joule losses in the windings of stator and rotor (including ohmic and frequency-dependent effects) and mechanical behavior have the highest impact on duty cycle losses and ultimately driving range of an electric vehicle.

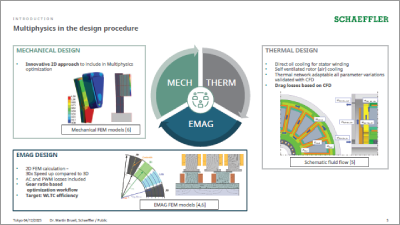

Connecting these domains and demands is mandatory in the Multiphysics design optimization of EEAFMs. For time-efficient calculations leading to extensive parameter studies, typical 3D simulations of the electromagnetic, mechanical and aerodynamic domains must be avoided as much as possible. In this work, several valid simplifications and model reductions have led to a significant reduction in simulation time while maintaining precise results.

Electromagnetically, the 2D circumferential sliced models are already known and well researched. The advantage of this method is the fast calculation and simultaneous representation of physical results such as nonlinear saturation behavior from the magnetic characteristics of the silicon steel laminations. The simulated torque and losses of the electric machine are assessed and verified for their prediction accuracy. Another 2D simplified model, perpendicular to the electromagnetic one is used to analyze the displacement and stress within the rotating system and is validated with detailed 3D models. Finally, 3D CFD simulations provide insights into airflow patterns and especially drag losses, relevant for the loss calculations.

The proposed holistic design workflow can be used to find the optima for a given requirement on the component level. By extending the degree of freedom with variable gearbox ratios, the most suitable powertrain setup and architecture can be determined. This study highlights the importance of Multiphysics design optimization to maximize the performance and reliability (-60% of displacement possible) of EE-AFMs as demonstrated in the graphs below. Incorporating aerodynamic drag analysis alongside electromagnetic and mechanical considerations offers improved efficiency and extended lifetime for electric mobility applications.

『JMAGソフトウェア正規ユーザー(有償会員)』または『JMAG WEB MEMBER(無料会員)』でサインインが必要です。

『JMAG WEB MEMBER(無料会員)』へ登録することで、技術資料やそのほかの会員限定コンテンツを無料で閲覧できます。

登録されていない方は「新規会員登録」ボタンをクリックしてください。