Magnetic Field

- Sort condition

- Newest first

- Oldest first

- Large number of views

-

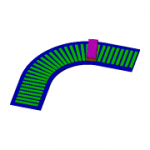

[JAC272] Thrust Analysis of Linear Actuator with a Curved Section

In this example, the thrust characteristics of a linear actuator with a curved section are obtained via analysis, and thrust at the transition from a linear motion to a curved mot…

-

Dai-ichi Kiden Co.,Ltd.

Providing customers with all new devices. Better products, faster service. Understanding the process one step at a time. New challenges with JMAG.

-

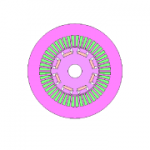

[JAC271] Axial Gap Type Motor AC Copper Loss Analysis

In this example, the AC copper loss of an axial gap type motor using square wire is evaluated.

-

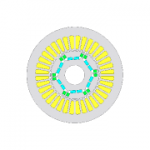

[JAC257] IPM Motor Topology Optimization

In this example, rotor core maximum stress and radial direction maximum displacement in the radial direction are set to certain values or less, and rotor geometry is designed that…

-

[JAC225] Induced Voltage Analysis on Memory Motors Using Variable Magnets

In this example, the change in motor characteristics are checked as the memory motor variable magnet magnetization is changed using the three-phase coil current. One example of mo…

-

[W-SE-145] Highly Parallel Solver Performance Evaluation (Induction Heating)

This document uses as an example an induction heating model to evaluate the performance of the highly parallel solver. As a result, it was found that even in thermal-magnetic fiel…

-

[JAC259] Automatically Searching for Current Phase that Obtains Maximum Torque and Evaluating Torque Characteristics

In this example, the current phase that maximizes the torque is searched for each of three rotor geometries. The motor average currents and torque ripples are evaluated using the …

-

[JAC258] Magnetic Shield Geometry Optimization

In this example, a case study in which the geometry of a magnetic shield is optimized using topology optimization that uses a sensitivity analysis (density method) is presented. D…

-

[L-HU-08] Complex 3D Models to FEA Models Within Short Timeframes

Amounts of processing required will increase proportionately to the number of parts. By applying parallel processing, mesher processing speed increases, and mesh generation time i…

-

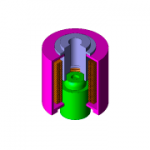

[JAC252] Geometry Optimization of a Solenoid Valve

In this example, an example where the geometry of a solenoid valve is optimized using a multi-objective optimization algorithm is presented.

-

[L-MA-04] New & Improved Iron Loss Analysis Function

When performing iron loss analysis, it is necessary to select optimal methods accounting for the likes of analysis targets, objectives, accuracy, types of usable data, and more.

-

[JAC261] SPM Motor Magnet Coercive Force Optimization For Obtaining Sinusoidal Magnetization

In this example, a magnet is segmented into blocks and coercive force is defined. The coercive force of each block is calculated so that the induced voltage waveform approaches a …

-

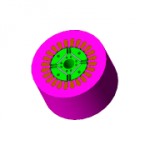

[W-MO-17] Alternator Analysis Using Tetrahedral/Pentahedral Mixed Mesh

This paper looks at tetrahedral/pentahedral mixed mesh and aims to generate effective mesh to reduce calculation time. We compared calculation times and accuracy when analysis is …

-

[L-HU-01] High Performance Parallel Solver Analyzing Complex Phenomena in Rotating Machines As Is

JMAG's high parallel solver exhibits high performance and has answers to a wide range of problems for in practice.

-

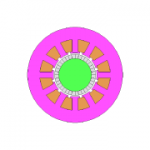

[JAC022] Analysis of the Eddy Current in the Magnet of an IPM Motor

This Application Note presents the use of a magnetic field analysis in a state of operation to obtain variations in magnet eddy current losses according to the number of divisions…

-

Initiatives in Toyota Vehicle Electrification and Developing Electrified Vehicles: Anticipating JMAG’s Support in the Development of Electrified Vehicles

Hideto Hanada, TOYOTA MOTOR CORPORATION