Electric Vehicle

Using models to develop traction motors

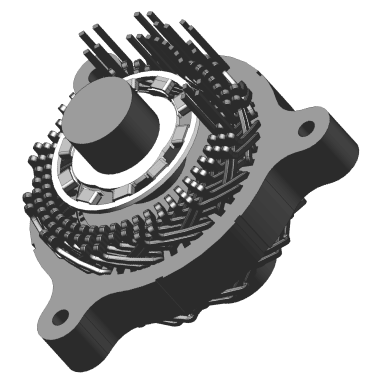

With the advancement of EV components, traction motors, in particular, are expected to exert high product performance in terms of low power consumption, high efficiency, high output, low vibration and noise, small size, and low cost. In addition to the performance of the motor alone, it is also necessary to satisfy the requirements and consistency of the inverters, ECU, gearboxes, etc. at the system level and JMAG contributes to the design and verification of these requirements.

One of the requirements for EV traction motors is to achieve high efficiency throughout the entire traction range of the motor in a limited development period. This type of design requires defining many design variables including dimensions and drive conditions, in addition to selecting a motor type. Furthermore, design exploration that extends over a range of individual design variables as wide as possible should be performed at high-speed. JMAG has actual machine level analysis accuracy required in global design exploration at the early design stage, in detailed design and in virtual prototyping and is capable of processing this sequence of design workflow at high-speed.

One of the requirements for EV traction motors is to achieve high efficiency throughout the entire traction range of the motor in a limited development period. This type of design requires defining many design variables including dimensions and drive conditions, in addition to selecting a motor type. Furthermore, design exploration that extends over a range of individual design variables as wide as possible should be performed at high-speed. JMAG has actual machine level analysis accuracy required in global design exploration at the early design stage, in detailed design and in virtual prototyping and is capable of processing this sequence of design workflow at high-speed.

Examples of development

The motor, a key component of electrification requires not only high performance but also high compatibility with the system.

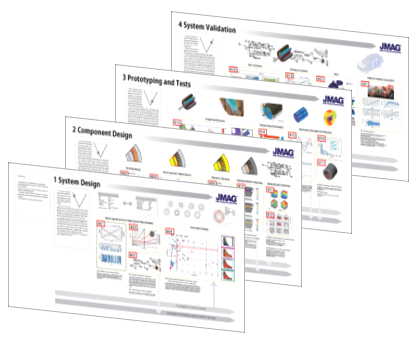

Model-based development, that makes use of simulation is becoming essential in motor development.

JMAG, with a strong track record in motor design, proposes a new workflow for model-based development.

The case study shows the details of the actual process of EV motor development from system design, component design, prototyping and performance evaluation through to system verification.

Model-based development, that makes use of simulation is becoming essential in motor development.

JMAG, with a strong track record in motor design, proposes a new workflow for model-based development.

The case study shows the details of the actual process of EV motor development from system design, component design, prototyping and performance evaluation through to system verification.

Case study

Kensuke Sasaki, Nissan Motor Co., Ltd.

Makoto Kawaguchi, Mazda Motor Corporation

Takashi Kawaguchi, Honda Motor Co., Ltd.

Toshifumi Yamakawa, TOYOTA MOTOR CORPORATION

Yoshihisa Kubota, Honda R&D Co.,Ltd

Marin Vulic, Rimac Automobili d.o.o.

Bharadwaj Raghuraman/Shafigh Nategh, Volvo Car Corporation

Tomoya Ueda, NIDEC CORPORATION

Tim Schwartz / Sebastian Igel, Great Wall Motor Austria Research & Development GmbH

Jihyun Kim, General Motors

Sukhwa Jung, DENSO CORPORATION

Daniel Keller, Mercedes Benz AG

Hideto Hanada, TOYOTA MOTOR CORPORATION

David Philipp Morisco, Robert Bosch GmbH