JMAG-Designer Ver. 21.0 was released in February 2022,

In JMAG-Designer Ver.21.0, creating models for control, circuits, and windings has become easier than ever, and the calculation speed and processing speed of operations have been increased to improve the efficiency of analysis work.

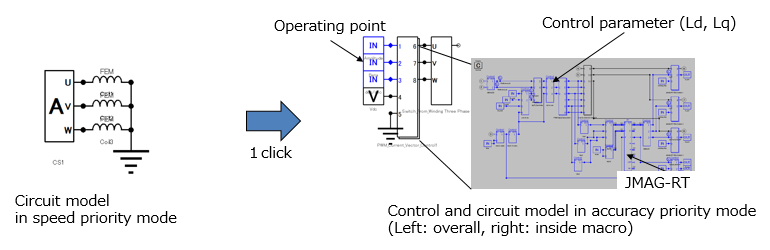

An efficiency map analysis study in accuracy-priority mode can be generated with a single click from an efficiency map analysis study in speed-priority mode. This makes it easy to build control models for accurate efficiency map evaluation. The control calculation speed has also been improved.

It is now possible to use multiple FEA models in an integration study. By increasing the accuracy of control and circuit models, as well as the models of peripheral devices such as sensors, the accuracy of the evaluation of target device characteristics can be improved. In addition, thermal circuit components for cooling have been added, making it easier to perform characteristic evaluations that take cooling into account.

The calculation speed of large-scale models and the pre-post processing speed have been improved. It is now possible to analyze models with a large number of parts and elements that are close to actual machines in a shorter time than before.

We encourage all our users to make the most of this latest version of JMAG with its many new enhancements.

What is JMAG-Designer Ver.21.0 ?

INDEX

- Automatic Conversion from Speed Priority Mode to Accuracy Priority Mode

- Macro Component of Current Vector Control

- Improved Calculation Speeds of Control Calculations

- Multiple FEA Model Support in the Integration Study

- Temperature Evaluation of Motor Accounting for Cooling

- Speedup of MPP Solver (Magnetic)

- Speedup of MPP Solver (Thermal and Magnetic)

- Speedup Mesh Generation

- Large Model Performance Improvement of Geometry Editor

Reduced control model creation time to obtain efficiency maps.

Control and circuit model creation in accuracy priority mode

Control and circuit model creation in accuracy priority mode

A study of the accuracy priority mode can be created with one-click from the speed priority mode. A JMAG-RT model output, the operating point and Ld Lq inheritance, control circuit creation, conversion from FEM coil conditions to FEM conductor conditions, etc. are carried out automatically.

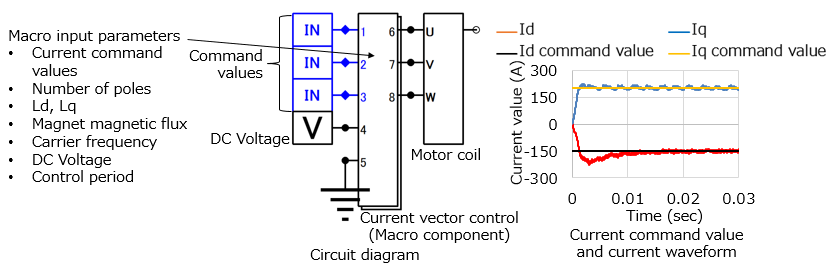

Current vector control can be constructed by specifying only parameters.

Macro component of the current vector control

Macro component of the current vector control

Control and inverter parts are prepared as a macro component. A control model can be created simply by setting the motor parameters such as the number of poles and Ld, Lq,etc.

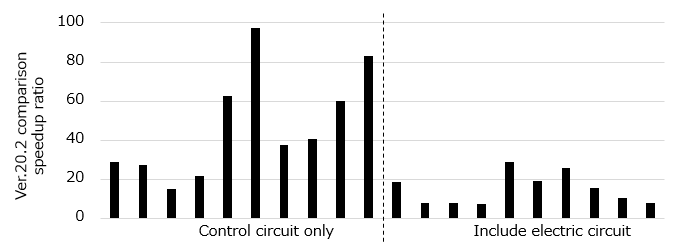

Eliminate speed delay of control calculations with multiple steps.

Speedup ratio of control calculation

Speedup ratio of control calculation

The speedup ratio is measured in 20,000 steps of control calculation, including the control circuit only and the electrical circuit (neither of them has FEA calculation). The result output processing and the calculation of the control circuit part is speeded up in Ver. 21.0, so a higher speedup ratio can be obtained in the case of the control circuit only.

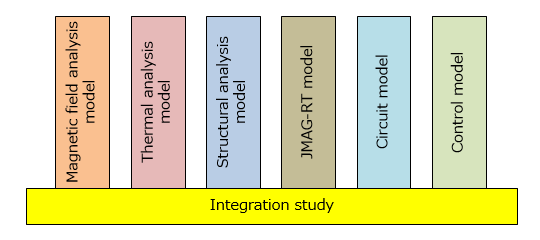

The equipment characteristics is evaluated in multi-domain.

Equipment characteristic evaluation by integration study

Equipment characteristic evaluation by integration study

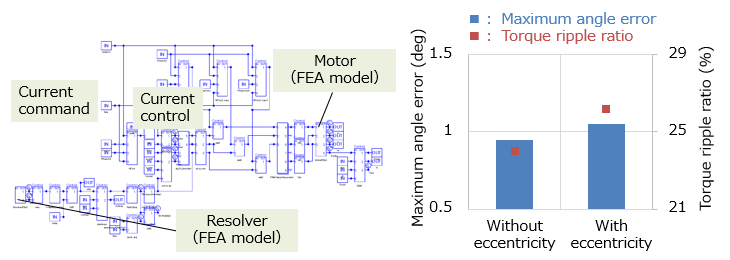

The integration study enables the evaluation of equipment characteristics with analysis that account for models of different domains. Ver.21.0 supports analysis of multiple FEA models with the same control and circuit model.

It is possible to simulate coordinated operation of multiple detailed models.

Effect of resolver angle detection error during dynamic eccentricity on motor characteristics

Effect of resolver angle detection error during dynamic eccentricity on motor characteristics

The effect of eccentricity of the resolver on the system can be considered using a model of the motor model with eccentricity. The resolver angle detection error is increased by eccentricity. It affects the torque ripple reduction control accounted for in control.

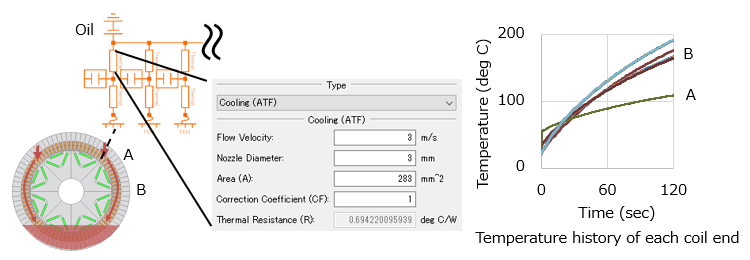

Cooling conditions can be modeled only with parameter settings.

Temperature evaluation of motor accounting for ATF cooling

Temperature evaluation of motor accounting for ATF cooling

Heat transfer from coil ends of the FEA model is connected to a heat circuit model, and the coil ends are connected to oil via thermal resistance. The thermal resistance of ATF is automatically calculated from the flow speed, diameter of the nozzle, and flow channel area. It can be modeled that the coil end temperature differs circumferentially depending on the position of the nozzle.

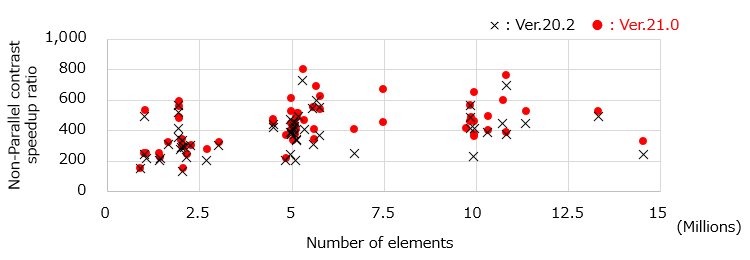

Analysis with a model that is more faithful to the actual machine.

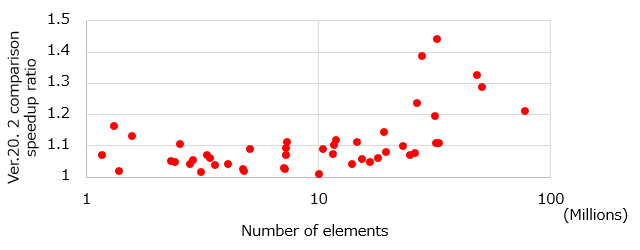

Number of elements and speed improvement ratio

Number of elements and speed improvement ratio

Speedup ratio is shown when applying 2,048 parallel. Measured for models with 1 million elements and more. Compared with the previous versions, the speedup ratio is improved with 10 million elements and more.

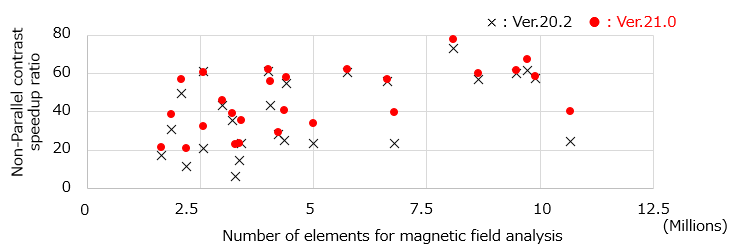

Improvement of model fidelity in thermal and magnetic field coupled analysis such as induction heating analysis.

Model size and speedup ratio

Model size and speedup ratio

Speedup ratio is shown when 128 processes are run in parallel for both magnetic field analysis and thermal analysis. Overall, speed is improved with 5 million elements and more.

Reduction of mesh generation time for large-scale models with a large number of elements.

Number of elements and speedup ratio

Number of elements and speedup ratio

The larger the number of elements, the higher the speedup ratio. Especially the ratio of improvement is more than 10% for models with 30 million elements and more.

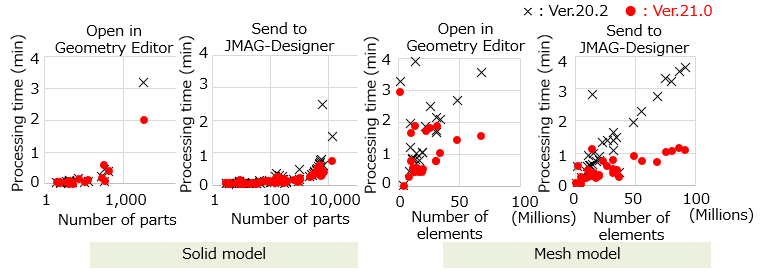

Improvement of efficiency during large-scale detailed model work.

Model size and Geometry Editor processing time

Model size and Geometry Editor processing time

Speedup processing of transferring data between Geometry Editor and JMAG-Designer with large-scale models that have a large number of parts and elements.

The new functions and Features

For details, please see the following function introduction. (PDF, 2.25MB: User authentication)

Introducing to new functions of JMAG-Designer Ver.21.0

Notes

- Notice of License Change for JMAG’s Standard Feature Link to SOLIDWORKS

- End of support for LM-X JMAG License Server Windows 32bit version

Documents

These are created using the functions in JMAG-Designer Ver.21.0 and later. Please feel free to use them.

Parametric, optimization

- [JFT152] Output of Response Values Using Surrogate Models

- [JFT153] Topology Optimization Calculations Using CNN Surrogate Models

Control / Circuit

- [JFT149] How to Create JMAG-RT Model with JMAG Designer and Run Consecutive Control Simulation

- [JFT150] Running Calculations of Multiple Studies Connected on Circuits

Multiphysics

Pre / Post Processer

Solver

Efficiency map

- [JAC278] Creating Six-Phase Induction Motor Efficiency Maps

- [JFT070] Creating PM Motor Efficiency Maps Using JMAG-Designer (Accuracy Priority Mode)

Module Download

The latest version of JMAG modules are available.

In addition, version information, release notes, manuals, etc. can be used. ( User authentication)

Video for Introducing the New Functions

A video complete with voice audio has been prepared to offer our users a better understanding of the new functions in JMAG-Designer Ver.21.0.

This is a lecture that can be attended via internet in your own time and for as many times as required.

Video for Introducing the New Functions of JMAG-Designer Ver.21.0

Introducing JMAG-Designer Ver.17.0 – Ver.23.1

Articles about JMAG-Designer that have been released previously are available.